2026 Top Packaging Machine Innovations to Watch for Future Trends?

The packaging machine industry is undergoing rapid transformation. With technological advancements, innovative solutions are emerging. According to a recent report by Smithers Pira, the global packaging machinery market is projected to reach $50 billion by 2026. This growth is driven by increased demand across various sectors, including food and beverages, pharmaceuticals, and cosmetics.

Emerging trends highlight sustainability and automation. Consumers are more eco-conscious, pushing companies to adopt greener packaging solutions. Automation improves efficiency, reducing human error. However, many companies struggle with implementation due to high initial costs. It's crucial for businesses to balance cost and innovation to stay competitive.

Future innovations in packaging machines will likely focus on smart technology and customization. For instance, IoT-enabled machines can optimize production processes. Customizable equipment can cater to diverse packaging needs. Yet, as innovations rapidly evolve, companies must continuously evaluate their strategies. The journey toward effective packaging solutions is not without challenges.

Future-Proofing with Sustainable Packaging Innovations in 2026

The packaging industry is evolving rapidly. Sustainable packaging solutions are becoming essential. In 2026, we can expect innovative materials that reduce waste. Biodegradable plastics and compostable packaging will lead the way. These materials can break down naturally, minimizing environmental impact. Eco-friendly inks and adhesives will also become more common. They will ensure that packaging remains safe for the planet.

Adopting these new materials is not without its challenges. Manufacturers must rethink their processes and supply chains. Transitioning to sustainable solutions may require significant investment. Some businesses might struggle to scale these innovations effectively. There may also be short-term cost increases. However, the long-term benefits could be substantial. Companies that embrace sustainable practices can boost their brand image. They can appeal to environmentally conscious consumers.

With sustainability at the forefront, we should not overlook education. Helping consumers understand the importance of eco-friendly packaging can drive change. Improving recycling rates is vital. Educating about proper disposal methods can lead to better outcomes for our planet. The future is bright, but we must stay committed to improving our practices. Sustainability is an ongoing journey, not just a destination.

Advancements in Smart Packaging Technologies for Enhanced User Experience

Smart packaging technology is transforming how consumers interact with products. This innovation enhances user experience by integrating digital features into packaging. Imagine a cereal box that connects to a smartphone app. It offers recipes based on what’s inside. This makes breakfast more engaging and personalized.

Another exciting development is environmentally friendly smart packaging. This type often uses biodegradable materials. It can also include QR codes that consumers scan to learn about recycling practices. This encourages eco-conscious behavior, but not everyone remembers to recycle. There’s still a long way to go in educating users about proper disposal.

Real-time tracking is also on the rise. Packaging with built-in sensors can inform users about freshness. It might warn if food is about to spoil. While this sounds useful, some consumers may find it overwhelming. They might prefer simpler, less intrusive options. The balance between innovation and user comfort remains a challenge for the industry.

Integrating AI and IoT in Packaging Machinery: Trends for 2026

The integration of AI and IoT in packaging machinery is revolutionizing the industry. Reports indicate that by 2026, the market for smart packaging solutions will exceed $20 billion. This growth is driven by efficiency and customization. Companies are now using AI to predict maintenance needs, reducing downtime significantly.

IoT devices are providing real-time data on production lines. These insights help manufacturers optimize operations. However, challenges remain. Not all companies have the infrastructure to support IoT integration. Security risks associated with data sharing have also raised concerns.

AI algorithms can improve packaging design and supply chain management. They offer insights into consumer preferences, making it easier to tailor products. Yet, these technologies can become complex. Not every employee is trained to work with them, leading to a skill gap. Companies should invest in training and adaptability to harness the full potential of these innovations.

Key Players and Market Trends Shaping the Packaging Industry by 2026

The packaging industry is transforming rapidly. By 2026, key trends will influence its direction. According to a report from Market Research Future, the global packaging market is expected to reach $500 billion. Sustainable materials are gaining traction. Nearly 70% of consumers prefer eco-friendly packaging. This shift is reshaping how brands approach their packaging strategies.

Automation is on the rise. Packaging machines are becoming smarter and more efficient. The demand for high-speed filling and sealing machines is increasing. Reports indicate a growth rate of 4.2% in the automated packaging segment. This trend enhances productivity but raises questions about the workforce. Finding skilled labor to operate these advanced systems can be challenging.

Tips: Consider using plant-based materials. They can reduce your carbon footprint. Explore innovative designs that attract consumers while being functional. Balancing aesthetics with practicality is crucial. Expect continuous changes in regulations surrounding packaging. Keeping up with these developments is essential for strong market performance.

Regulatory Compliance and Safety Standards for Future Packaging Solutions

In the evolving landscape of packaging, regulatory compliance is paramount. Ensuring that packaging materials meet safety standards is crucial. This extends to food safety, environmental impact, and consumer protection. New innovations must align with regulations to avoid costly recalls and legal issues.

Many companies are still in a reactive mode. They often wait for regulations to change before adapting. This is a risky approach, especially with evolving consumer expectations. Smart packaging technologies, like QR codes, can provide essential information to consumers. However, organizations must ensure these technologies are compliant.

Sustainability must not be overlooked. The demand for eco-friendly materials is growing. Yet, achieving compliance with both environmental goals and safety regulations can be challenging. Companies must navigate a complex landscape. Balancing innovation with responsibility requires careful planning and foresight. It is not just about compliance; it is about building trust with consumers.

Related Posts

-

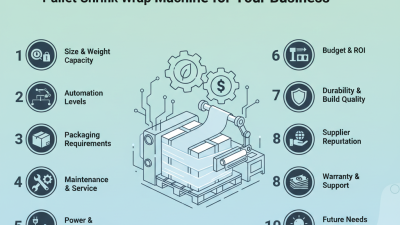

Top 10 Tips for Choosing the Best Pallet Shrink Wrap Machine for Your Business

-

Top 10 Benefits of Using a Plastic Strapping Machine for Packaging Solutions

-

Why You Need a Plastic Banding Machine for Your Packaging Operations

-

How to Choose the Best Automatic Pallet Wrapping Machine for Your Business

-

Top 10 Benefits of Using Automatic Stretch Wrap Machines for Your Business

-

Top 10 Tips for Choosing the Best Box Taping Machine for Your Needs