Top 10 Benefits of Using Automatic Stretch Wrap Machines for Your Business

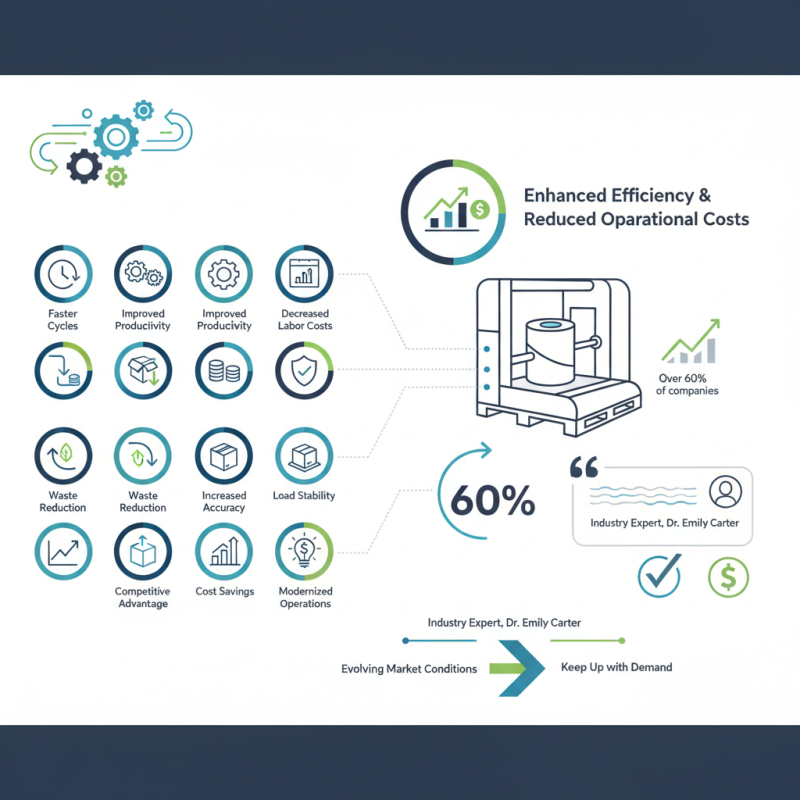

In today's fast-paced industrial environment, businesses are constantly seeking ways to enhance efficiency and reduce operational costs. One such advancement that has gained significant traction is the adoption of automatic stretch wrap machines. According to the 2022 Packaging Automation Report, over 60% of companies that utilize automated packaging solutions reported a marked improvement in their productivity levels. These machines not only streamline the packaging process but also provide cost savings that can greatly impact the bottom line.

Industry expert, Dr. Emily Carter, a renowned packaging technology researcher, states, "The integration of automatic stretch wrap machines into packaging lines can lead to substantial decreases in labor costs, while simultaneously increasing packaging accuracy and load stability." This highlights the critical role that such technology plays in modernizing operations. The benefits extend beyond just financial savings; they also encompass improved safety, waste reduction, and faster packaging cycles. As businesses strive to keep up with demand and evolving market conditions, the shift towards automatic stretch wrap machines helps ensure they remain competitive and efficient in their operations.

Benefits of Increased Efficiency in Packaging Operations

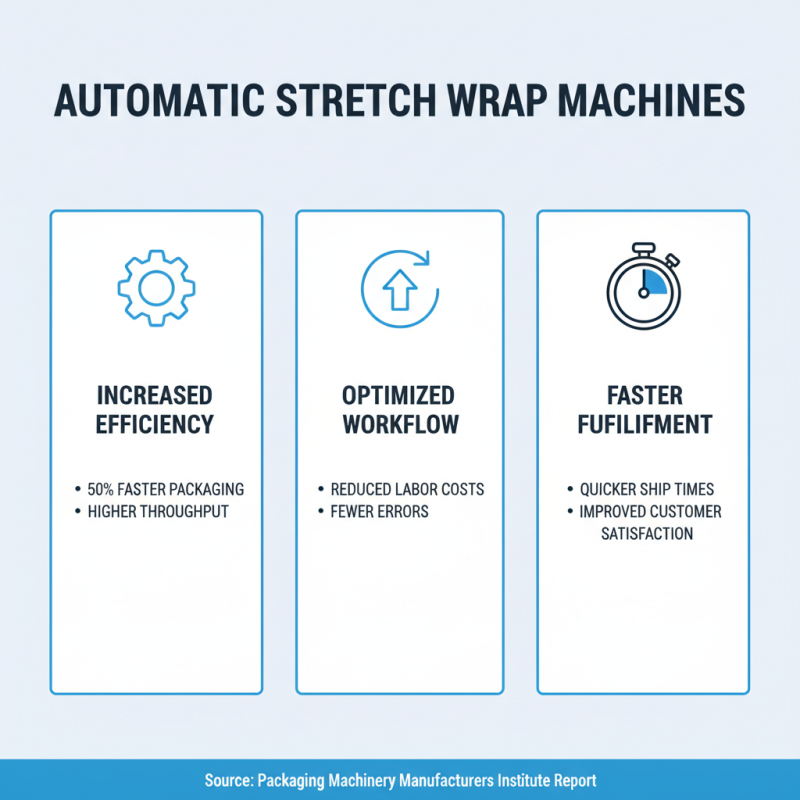

Automatic stretch wrap machines have transformed the way businesses approach packaging operations, significantly enhancing overall efficiency. According to a report by the Packaging Machinery Manufacturers Institute, automating packaging processes can boost efficiency by up to 50%, allowing companies to handle higher volumes with the same workforce. This level of productivity not only streamlines the workflow but also reduces the time spent on manual wrapping, which often leads to delays and errors. By integrating these machines, organizations can speed up their packaging lines, leading to quicker shipment times and improved customer satisfaction.

Moreover, automatic stretch wrap machines contribute to consistency in packaging quality. A study published in the Journal of Packaging Technology and Research indicates that automated systems can reduce material waste by up to 20%, as they apply just the right amount of stretch film required for each load. This increased precision not only optimizes material usage but also minimizes the risk of product damage during transit, ultimately protecting the company's bottom line. In an industry where margins can be tight, investing in such technology can provide a competitive edge by maximizing output while ensuring that products are secure and presented well to customers.

Enhancements in Product Protection and Stability

Automatic stretch wrap machines play a crucial role in enhancing product protection and stability during storage and transportation. According to a report by the Packaging Industry Association, nearly 30% of products suffer damage during transit, leading to significant losses for businesses. Implementing automatic stretch wrapping can reduce these losses by up to 70% through uniform and secure wrapping that protects items from dust, moisture, and physical damage. Moreover, consistent tension and layering in automatic systems help maintain the integrity of the packaged goods, minimizing the risk of shifting or collapsing during handling.

In addition to safeguarding products, these machines also contribute to stability in the supply chain. A study from the Institute of Packaging Professionals found that using stretch wrap can improve load stability by 50% compared to hand wrapping methods. This increased stability not only ensures that products arrive in optimal condition but also helps streamline logistics operations. With better stackability and less occurrence of breakage, companies can achieve higher efficiency and potentially reduce transportation costs, ultimately enhancing the overall bottom line of the business. The investment in automatic stretch wrap machines is not just about protecting products; it's about reinforcing the reliability and efficiency of the entire supply chain.

Top 10 Benefits of Using Automatic Stretch Wrap Machines for Your Business

| Benefit | Description | Impact |

|---|---|---|

| Enhanced Product Protection | Automatic stretch wrap machines provide consistent wrapping, reducing the risk of damage during transportation. | Minimized product loss and returns due to damage. |

| Increased Efficiency | These machines can wrap products faster than manual methods, speeding up the packaging process. | Higher output and reduced labor costs. |

| Consistency in Wrapping | Machines ensure uniform wrapping tension and thickness, providing a reliable safeguard for the products. | Improved brand reputation through quality presentation. |

| Cost Savings | Reduced material usage due to optimal wrapping and automation of the process. | Lower packaging costs over time. |

| Space Efficiency | Automatic machines are designed to occupy minimal floor space while maximizing productivity. | Better utilization of warehouse space. |

| Reduction in Labor Efforts | Machines require fewer operators than manual wrapping processes, allowing staff to focus on other tasks. | Increased workforce productivity. |

| Flexibility and Scalability | Adjustable settings allow for wrapping of various product sizes and shapes. | Ability to adapt to changing product lines. |

| Improved Safety | Reduces the ergonomic risks associated with manual wrapping tasks. | Lower injury rates and associated costs. |

| Enhanced Visual Appeal | Consistent wrapping enhances the aesthetic of product displays. | Attractive presentations can increase customer satisfaction. |

| Environmental Benefits | Modern machines use less film material, promoting sustainability practices. | Contributes to corporate social responsibility efforts. |

Reduction of Labor Costs Through Automation

The implementation of automatic stretch wrap machines in businesses has led to a significant reduction in labor costs, primarily through the automation of repetitive tasks. By minimizing the need for manual labor in the wrapping process, companies can reallocate their workforce to more strategic roles. This not only enhances productivity but also allows businesses to operate with fewer personnel, ultimately lowering payroll expenses.

One important tip for businesses looking to transition to automated stretch wrapping is to conduct a thorough analysis of their current packaging processes. Understanding where bottlenecks occur and how much time is spent on manual wrapping can help demonstrate the potential savings from automation. Additionally, employees should be trained to work alongside the machines effectively, ensuring a smooth integration into their daily operations.

Another consideration is the variety of loads being wrapped. Different products may require specific wrapping techniques to ensure safety and integrity during transportation. Choosing an automatic stretch wrap machine that can adapt to a range of load sizes and shapes will further optimize efficiency and cost savings. By investing in the right equipment and training, businesses can significantly enhance their operational efficiencies while reducing labor costs.

Top 10 Benefits of Using Automatic Stretch Wrap Machines for Your Business

This chart illustrates the top 10 benefits of using automatic stretch wrap machines in a business setting, with an impact score reflecting their significance in operational efficiency and cost savings.

Improved Consistency and Quality in Wrapping

Automatic stretch wrap machines have transformed the packaging industry by providing improved consistency and quality in the wrapping process. According to a report by The Packaging Association, businesses that utilize automatic wrapping systems can achieve a 15-20% reduction in packaging errors, which significantly enhances the quality of wrapped products. This consistent application of stretch film not only protects goods but also ensures uniformity across batches, thereby elevating brand reputation and customer satisfaction.

One of the key advantages of automatic stretch wrap machines is their ability to apply the optimal amount of film consistently. The machinery is programmed to adjust the tension and overlap based on the type and weight of the load, which minimizes film usage while maximizing strength. A study by the Institute of Packaging Professionals found that businesses experienced a 25% reduction in film costs when switching from manual to automated systems. This careful application not only strengthens the load but also reduces waste, benefitting both the environment and the company's bottom line.

**Tip:** To maximize the benefits of automatic stretch wrapping, regularly maintain your machines to ensure they operate at peak efficiency. Routine checks and timely replacements of wear components can prevent inconsistencies that may arise from equipment failures.

**Tip:** Train your staff on the specific capabilities and settings of your automatic wrapping machines. Understanding how to optimize settings for different products can further enhance the quality of your packaging, ensuring that every load meets your quality standards.

Minimization of Material Waste and Costs

The minimization of material waste and costs is a significant advantage offered by automatic stretch wrap machines. Traditional hand wrapping methods often lead to excessive use of plastic film, resulting in considerable waste and increased operational costs. These machines, on the other hand, utilize advanced technology to apply just the right amount of film to secure products efficiently. This precision reduces the amount of plastic used while ensuring that items are adequately protected during transportation and storage.

Additionally, automatic stretch wrap machines help streamline the wrapping process, which can lead to lower labor costs. By automating this task, businesses can reduce the time and manpower required for packaging, allowing staff to focus on other critical areas of production. With less plastic film wasted and more efficient use of labor resources, businesses can significantly enhance their bottom line while committing to more sustainable practices. Ultimately, the integration of automatic stretch wrap machines not only helps in cutting down costs but also supports environmental stewardship by reducing plastic consumption.