Top Benefits of Using Strapping Machines in Modern Packaging Solutions

In today's fast-paced industrial environment, the importance of efficient packaging solutions cannot be overstated. Businesses are constantly seeking ways to enhance their productivity, reduce costs, and meet the growing demands of consumer satisfaction. One indispensable tool that has emerged in modern packaging solutions is the strapping machine. These machines provide a robust and reliable method for securing packages, ensuring that goods remain intact during storage and transportation.

The use of strapping machines allows companies to streamline their packaging processes, effectively reducing manual labor and minimizing the risk of injury associated with traditional packing methods. Moreover, strapping machines can accommodate a variety of materials and package sizes, providing versatility and adaptability to meet specific business needs. With benefits such as increased operational efficiency, enhanced durability of packaged goods, and improved presentation, strapping machines play a crucial role in the evolution of packaging technology. As we explore the top benefits of integrating strapping machines into modern packaging solutions, we will uncover how these machines not only optimize performance but also contribute to overall business growth.

Advantages of Strapping Machines in Packaging Efficiency

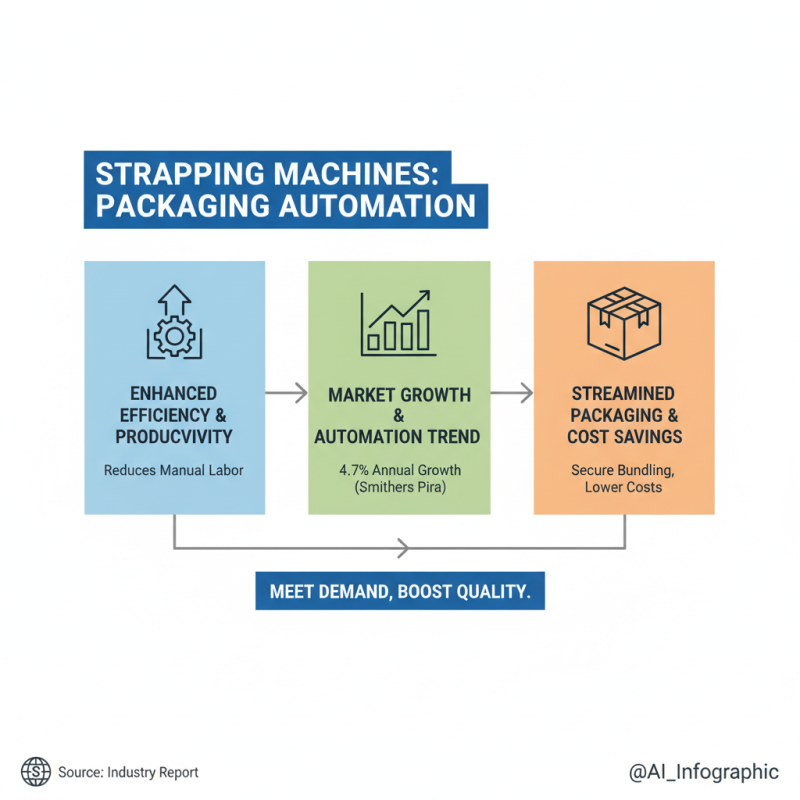

Strapping machines have become indispensable in modern packaging solutions, greatly enhancing efficiency and productivity in various industries. According to a recent industry report from Smithers Pira, the packaging machinery market is projected to grow by 4.7% annually, with a significant shift towards automation. Strapping machines, in particular, streamline the packaging process by securely bundling products, reducing the time required for manual packaging tasks. This efficiency translates into lower labor costs and increased throughput, enabling businesses to meet rising demand without compromising on quality.

In addition to improving operational efficiency, strapping machines contribute to better product protection during transit. A study by Freedonia Group highlighted that properly strapped packages can reduce damages by up to 30%, thereby decreasing the costs associated with returns and replacements. This is particularly crucial in industries where product integrity is paramount, such as logistics and food packaging. By investing in advanced strapping technology, companies can ensure their goods remain secure throughout the supply chain, minimizing spoilage and loss. Furthermore, automated strapping machines can adapt to various package sizes and materials, leading to greater flexibility and scalability in production lines.

Enhancing Product Security through Strapping Technology

Strapping technology plays a crucial role in enhancing product security in modern packaging solutions. By using strapping machines, businesses can ensure that their products are securely bundled and protected during transportation and storage. This is especially vital for items that are heavy, irregularly shaped, or vulnerable to damage. Strapping not only prevents shifting during transport but also deters potential tampering or theft, providing peace of mind to both manufacturers and consumers.

When implementing strapping technology, consider the following tips to maximize efficacy. First, choose the right strapping materials based on the nature of the products being packaged. For instance, polypropylene straps offer lightweight protection while polyester straps provide superior strength for heavier items. Additionally, ensure that the tension applied during the strapping process is adequate to secure the load without risk of damaging the products. Regular equipment maintenance is also essential; a well-maintained strapping machine ensures consistent performance and reduces the likelihood of packaging errors.

Furthermore, integrating automation in the strapping process can significantly boost efficiency and accuracy. Automated strapping machines minimize human error and increase throughput, allowing for faster production times without compromising on security. As packaging demands continue to grow, harnessing the benefits of strapping technology can effectively safeguard products while optimizing operational workflows.

Top Benefits of Using Strapping Machines in Modern Packaging Solutions

This chart illustrates the top benefits of using strapping machines in modern packaging solutions. The data reflects the significance of each benefit, showcasing how effective strapping technology enhances product security and overall efficiency in the packaging industry.

Cost-Effectiveness of Automated Strapping Solutions

Automated strapping solutions have emerged as a cost-effective alternative to traditional packaging methods, revolutionizing the way businesses handle their shipping and storage needs. The initial investment in strapping machines may seem substantial, but the long-term savings often outweigh this outlay. By streamlining the packing process, these machines significantly reduce labor costs associated with manual strapping. Automated systems can complete tasks more quickly and with greater consistency, ensuring that packaging is secure and reduces the likelihood of product damage during transit.

Moreover, the efficiency of automated strapping machines translates into enhanced productivity. Businesses can optimize their operations by integrating these machines into their workflows, allowing for faster turnaround times and reduced bottlenecks during peak shipping periods. With reduced packing times and improved accuracy, companies can increase their shipping capacity without the need to hire additional staff. This combination of lower operational costs and increased output makes automated strapping an appealing choice for businesses aiming to improve their overall packaging processes while maintaining profitability.

Versatility of Strapping Machines in Various Industries

Strapping machines have become essential tools across various industries due to their impressive versatility and efficiency. These machines are designed to secure products into bundles, pallets, and other configurations, making them invaluable in sectors such as logistics, manufacturing, and even food packaging. The global strapping machine market was valued at approximately $5 billion in 2021 and is projected to grow substantially, with an estimated CAGR of 6.5% through 2028, indicating a rising demand for efficient packaging solutions across multiple fields.

One significant advantage of strapping machines is their adaptability to different materials and product types. Industries ranging from e-commerce to pharmaceuticals utilize these machines to ensure their goods are securely packaged for transportation and storage. For instance, in the construction industry, strapping machines are essential for bundling steel and other materials, enhancing safety and streamlining shipping processes. A recent study highlighted that automated strapping can improve packaging speed by up to 40%, minimizing labor costs and significantly increasing productivity, which is crucial in today’s fast-paced market environment.

In the food and beverage sector, strapping machines provide not only secure packaging but also compliance with hygiene standards, which is vital for maintaining product integrity. Reports have shown that automated packaging solutions can reduce waste significantly by optimizing the use of materials, making strapping machines not just a convenience but a strategic investment for modern manufacturing and packaging operations. As industries continue to adapt to changing consumer demands and economic pressures, the role of strapping machines in enhancing operational efficiency will likely grow even more prominent.

Streamlining Packaging Processes with Advanced Strapping Systems

The growing complexity of logistics and demands for efficiency in packaging have led many companies to adopt advanced strapping systems. These machineries not only enhance the speed of operations but also ensure more reliable and consistent packaging outcomes. According to a report by Smithers Pira, the global market for strapping machines is projected to grow at a compound annual growth rate of 6.3% through 2026, highlighting the increasing recognition of their value among manufacturers and distributors.

By streamlining processes through automated strapping solutions, businesses can significantly reduce labor costs and minimize human error. Automated systems can strap packages in a fraction of the time it takes to do so manually, resulting in increased throughput. A study by the Packaging Machinery Manufacturers Institute indicates that automation can improve packaging line efficiency by as much as 30%. Moreover, advanced strapping systems often include integrated sensors and monitoring technologies, providing real-time data that helps companies optimize their operations and reduce material waste, aligning with their sustainability goals.

Additionally, the use of strapping machines enhances package integrity and protection during transit, which is crucial for minimizing damage and loss. With the global e-commerce sector expected to reach $6.54 trillion by 2022, businesses are increasingly investing in robust packaging solutions to safeguard their products, ensuring customer satisfaction and loyalty. As logistics continue to evolve, the integration of advanced strapping technology stands as a pivotal trend in modern packaging solutions.

Top Benefits of Using Strapping Machines in Modern Packaging Solutions

| Benefits | Description | Impact on Efficiency |

|---|---|---|

| Increased Speed | Automated strapping machines can strap packages much faster than manual methods. | Reduces overall packaging time by up to 50%. |

| Consistent Quality | Ensures uniform tension and placement of straps, reducing risk of damage. | Minimizes product loss and return rates. |

| Labor Savings | Reduces the need for manual labor, allowing workforce reallocation. | Increases productivity across packaging operations. |

| Adaptability | Can handle a variety of package sizes and types with customization options. | Flexible solutions that suit diverse packaging needs. |

| Cost Efficiency | Investing in strapping machines can lead to long-term savings on materials and labor. | Offers a good return on investment by reducing operational costs. |

Related Posts

-

Top 10 Benefits of Using a Plastic Strapping Machine for Packaging Solutions

-

Essential Tips for Choosing the Best Automatic Banding Machine for Your Business

-

How to Choose the Best Air Pillow Machine for Your Packaging Needs

-

Top 10 Benefits of Using Automatic Stretch Wrap Machines for Your Business

-

Top 10 Tips for Choosing the Best Box Taping Machine for Your Needs

-

Why You Need a Plastic Banding Machine for Your Packaging Operations