2026 Best Stretch Wrap Machine for Efficient Packaging Solutions?

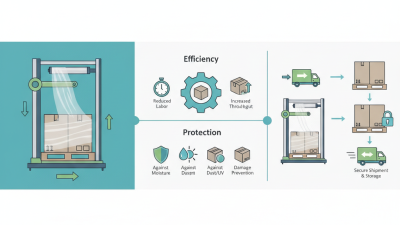

Efficient packaging is essential for any business. A stretch wrap machine plays a critical role in this process. It reduces manual labor and increases productivity.

Selecting the right stretch wrap machine can be challenging. Different models offer various features and capabilities. Some machines may lack durability and efficiency. Others might not fit your unique packaging needs.

Investing in a quality stretch wrap machine can enhance your operations. It ensures products are securely wrapped and protected during transport. Making the right choice requires careful consideration. Look for machines that provide effective solutions while being user-friendly.

2026 Key Features to Look for in a High-Performance Stretch Wrap Machine

When searching for a high-performance stretch wrap machine, certain features significantly enhance efficiency. First, look for adjustable tension settings. This allows users to modify the wrap tightness based on the load shape. Stronger tension ensures that items remain secure during transport. However, over-tensioning can lead to product damage. Balancing this is crucial.

Another vital feature is the machine’s speed. A faster wrap rate can boost productivity. Yet, high speed may compromise wrap quality. Consistency in application is key to avoiding load shifting. Additionally, consider the type of wrapping film compatibility. Machines that support various film thicknesses provide flexibility. However, not all films work well, leading to unnecessary waste. It is essential to test different films.

Lastly, user-friendly controls make operation simpler. Intuitive interfaces reduce training time. Frequent operator errors can occur with complex systems. A device with clear instructions can minimize stress. Pay attention to the machine’s maintenance requirements as well. Regular upkeep ensures longevity, but some machines may have tricky maintenance schedules. This can add to operational challenges, which is worth considering.

2026 Best Stretch Wrap Machine Efficiency Comparison

This chart compares the efficiency of three different stretch wrap machines based on four key features: Speed (units per hour), Film Roll Diameter (in inches), User-Friendliness (rated from 1 to 10), and Price in dollars. Analyzing these factors will help businesses choose the best machine to enhance their packaging solutions.

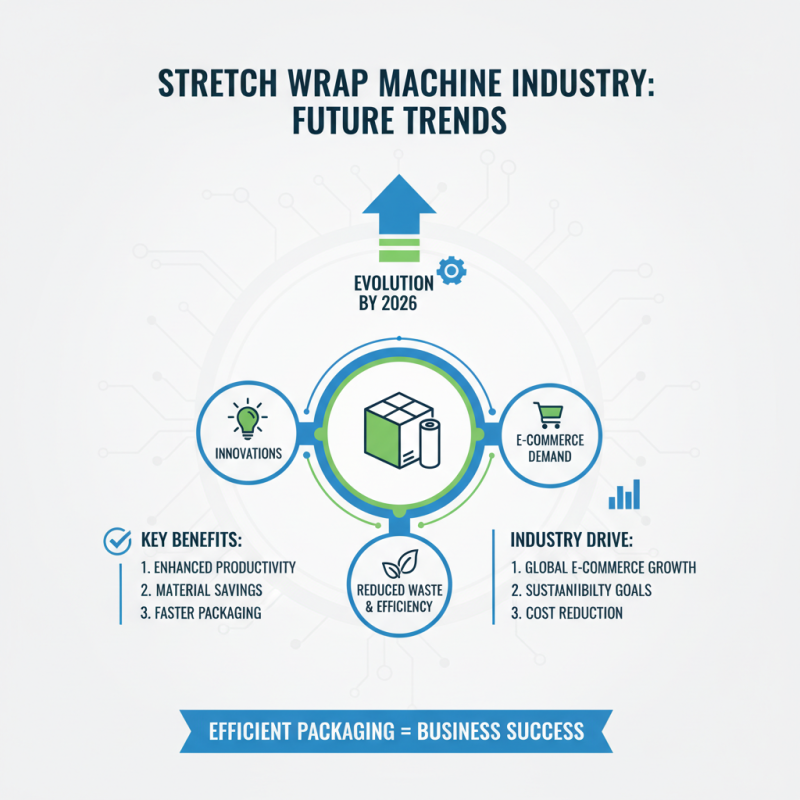

Industry Trends: Growth and Innovations in Stretch Wrap Machines by 2026

The stretch wrap machine industry is evolving rapidly. By 2026, we can expect significant innovations. Efficient packaging solutions are critical for businesses. With the rise of e-commerce, demand for advanced stretch wrap machines is increasing. These machines enhance productivity and reduce material waste.

Tips: Regular maintenance is key. Inspect the machine frequently. This will prevent unexpected breakdowns and costly downtime. Also, train staff thoroughly. Proper operation reduces errors and improves output.

Automated systems are becoming mainstream. They streamline the packaging process. However, high initial costs can be a hurdle. Small businesses may find it challenging to invest. Consider long-term benefits versus short-term expenses. This reflection can guide smart investment decisions. Adapting to new technologies might feel overwhelming. Start with gradual upgrades instead of a complete overhaul.

Comparative Analysis: Manual vs. Automatic Stretch Wrap Machines Efficiency

When comparing manual and automatic stretch wrap machines, efficiency is a key factor. Manual machines require more labor. Operators must wrap each pallet carefully, which can lead to inconsistencies. Productivity can suffer as workers tire or lose focus. Hours spent wrapping can accumulate quickly. Mistakes may happen, particularly when handling heavy or awkward loads.

On the other hand, automatic stretch wrap machines streamline the process. They wrap pallets uniformly and quickly, saving precious time. Operators can focus on other tasks. However, initial setup can be complex, and improper adjustments might lead to excess material use. This can increase costs and waste. Balancing speed with quality remains a challenge in many operations. Each method has unique advantages and drawbacks, prompting reflection on which suits specific needs best.

2026 Best Stretch Wrap Machine for Efficient Packaging Solutions

| Feature | Manual Stretch Wrap Machine | Automatic Stretch Wrap Machine |

|---|---|---|

| Initial Cost | $1,000 - $2,500 | $10,000 - $50,000 |

| Operating Speed | 20-30 wraps per minute | 40-100 wraps per minute |

| Labor Requirements | 1-2 operators | Minimal, usually 1 operator |

| Material Waste | Higher, as control depends on operator | Lower, precise wrapping |

| Ease of Use | Requires training | User-friendly interface |

| Footprint | Compact | Larger, requires more space |

| Maintenance | Low | Moderate to high |

Impact of Stretch Wrap Technology on Supply Chain Logistics Optimization

The impact of stretch wrap technology on supply chain logistics is profound. Efficient packaging can significantly reduce transportation costs. By securing products tightly, stretch wrap minimizes movement during transit. This protection leads to fewer damages and loss. However, it’s not just about sealing; it’s about optimizing space.

Poor wrapping techniques can result in wasted space and increased shipping expenses. A well-wrapped pallet maximizes load efficiency, allowing more products to fit in a vehicle. This can lead to fewer trips and lower fuel consumption. Still, companies sometimes overlook the importance of training staff. Inadequate knowledge about wrapping methods can lead to mistakes.

An effective stretch wrap machine can enhance consistency. It automates the wrapping process and increases speed. Yet, it may also require initial investment and maintenance costs. Firms need to balance up-front expenses with long-term savings. Understanding these trade-offs is key. Continuous reflection and adjustment are essential for maximum efficiency.

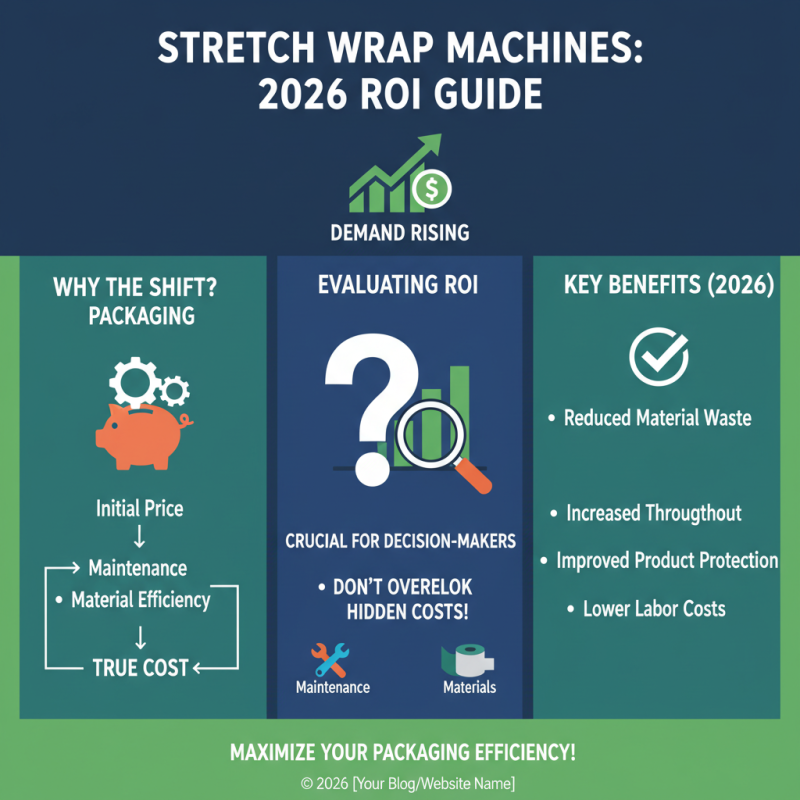

Cost-Effectiveness: Evaluating ROI of Modern Stretch Wrap Machines in 2026

In 2026, the demand for stretch wrap machines continues to rise. Businesses are recognizing the importance of cost-effectiveness in their packaging processes. Evaluating the return on investment (ROI) becomes crucial for decision-makers. Many companies overlook the actual costs involved. They might focus on the initial price, not considering maintenance or material efficiency.

Investing in modern stretch wrap machines often leads to reduced material waste. These machines can optimize the amount of film used, saving costs long-term. Yet, some companies fail to analyze this aspect deeply. A thorough audit of current practices can reveal hidden savings. For example, if a company wraps fewer pallets per hour, the hidden labor costs can add up quickly.

**Tips:** Calculate the cost per pallet wrapped. Compare different machine models on their efficiency. Don't just stick to the lowest price. Consider the total cost of ownership over several years. More expensive machines might offer better durability and lower maintenance costs in the long run. Reflect on habitually used materials; switching to better-quality films can improve efficiency.

Related Posts

-

Top 10 Benefits of Using Automatic Stretch Wrap Machines for Your Business

-

What is an Automatic Pallet Wrapping Machine and How Does It Work?

-

How to Choose the Best Shrink Wrap Machine for Your Business Needs

-

Top 10 Tips for Choosing the Best Box Taping Machine for Your Needs

-

Best Air Cushion Machine for Optimal Packaging Efficiency and Cost Savings

-

Essential Tips for Choosing the Best Automatic Banding Machine for Your Business