How to Choose the Best Pallet Shrink Wrap Machine for Your Business Needs

In the evolving landscape of logistics and packaging, the decision to invest in a pallet shrink wrap machine can significantly impact operational efficiency and product safety. According to industry expert James Williams, a recognized consultant in packaging solutions, "Choosing the right pallet shrink wrap machine is not just about cost; it’s about understanding your specific needs and how the machinery can enhance your workflow." This statement underscores the importance of a tailored approach when selecting packaging equipment.

As businesses increasingly seek ways to streamline their operations and protect their products during transportation and storage, the right pallet shrink wrap machine can provide a host of benefits. From ensuring items remain tightly bundled during transit to reducing shrink film wastage, the functionality of these machines can vary widely based on their design and technology. It is crucial for business owners to thoroughly evaluate their packaging requirements and consider factors such as throughput, ease of use, and maintenance.

By understanding the diverse options available and aligning them with their specific operational needs, companies can maximize their investment and improve efficiency in their supply chain. This guide aims to demystify the selection process for pallet shrink wrap machines, providing insights that will help you make informed decisions that align with your business goals.

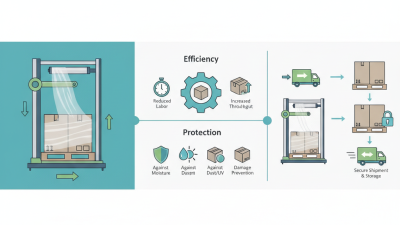

How Pallet Shrink Wrap Machines Enhance Packaging Efficiency

Pallet shrink wrap machines have become essential tools in enhancing packaging efficiency across various industries. According to a report by Smithers Pira, the global market for packaging machinery is projected to reach over $60 billion by 2024, driven largely by innovations in automation and packaging technologies. These machines streamline the wrapping process, allowing businesses to package pallets quickly and consistently, ultimately reducing labor costs and minimizing product damage during transportation.

When selecting a pallet shrink wrap machine, understanding its impact on packaging efficiency is crucial. A study conducted by the Packaging Machinery Manufacturers Institute (PMMI) found that companies utilizing automated shrink wrap systems improved their packaging throughput by up to 30% compared to manual methods. This increase is not only due to reduced labor but also because automated machines minimize human error, ensuring that each pallet is secured properly with consistent application of shrink film. Furthermore, with the advent of advanced machinery featuring adjustable settings for different product sizes and types, businesses can easily adapt to varying demands without sacrificing speed or quality.

Key Factors to Consider When Selecting a Shrink Wrap Machine

When selecting a pallet shrink wrap machine, several key factors should be considered to ensure it meets the specific requirements of your business. First, assess the type and size of the products being packaged. The machine must accommodate the dimensions and weight of your pallets, as well as the packaging materials you'll be using. Understanding the volume of products that will be processed is also crucial; high-throughput operations may necessitate more advanced machines with faster cycle times and automated features.

Another important factor is the shrink wrap film's compatibility with the machine. Different films have varying thicknesses and properties that can affect the sealing process and durability of the package. Additionally, consider the machine's ease of use and maintenance requirements. A user-friendly interface will reduce training time for operators, while machines that require minimal maintenance can enhance overall efficiency and productivity. Finally, evaluate energy consumption and overall operational costs, as these can significantly impact long-term profitability. By carefully considering these factors, businesses can select the most suitable pallet shrink wrap machine to enhance their packaging processes.

Comparison of Key Features in Pallet Shrink Wrap Machines

Understanding Different Types of Pallet Shrink Wrap Machines

When selecting a pallet shrink wrap machine for your business, understanding the different types available is crucial for meeting your operational needs. There are primarily three types of pallet shrink wrap machines: manual, semi-automatic, and fully automatic. Manual machines are often favored by smaller operations due to their lower upfront cost, but they require more labor and time. Semi-automatic machines provide a balance of efficiency and cost-effectiveness, usually featuring automated film cutting and sealing but requiring operator setup. Fully automatic machines, while more costly, offer the highest throughput and efficiency, making them ideal for larger businesses with high-volume packaging needs.

According to industry reports, demand for pallet shrink wrap machines is projected to grow at a compound annual growth rate (CAGR) of approximately 4.5% through 2026. This growth is largely driven by increased automation in packaging processes and the need for greater product protection during transport. Choosing the right machine not only impacts your operational efficiency but also influences your overall packaging costs.

Tips: When evaluating your options, consider the machine's output capacity, ease of use, and maintenance requirements. Additionally, ensure that the machine is compatible with your current packaging materials to avoid unnecessary expenses. It’s also beneficial to assess the training and support provided by the manufacturer, as this can greatly reduce downtime and improve employee efficiency.

How to Choose the Best Pallet Shrink Wrap Machine for Your Business Needs

| Machine Type | Purpose | Max Load Capacity | Speed | Power Requirement |

|---|---|---|---|---|

| Manual Shrink Wrap Machine | Small to medium-sized businesses | Up to 1,500 lbs | 10-20 packages per hour | 120V, 15A |

| Semi-Automatic Shrink Wrap Machine | Medium-sized businesses | Up to 3,000 lbs | 30-50 packages per hour | 220V, 30A |

| Automatic Shrink Wrap Machine | Large manufacturers | Up to 5,000 lbs | 100-200 packages per hour | 380V, 50A |

| Shrink Wrap Tunnel | High-volume production | Unlimited with proper support | 200+ packages per hour | 300V, 40A |

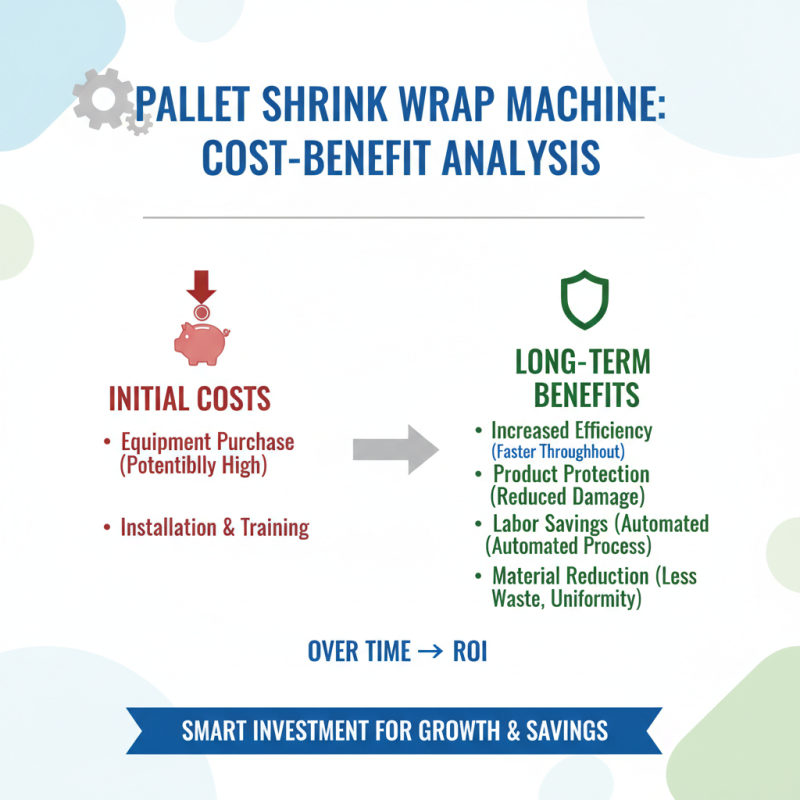

Analyzing Cost vs. Benefit of Investing in Shrink Wrap Equipment

When considering the investment in a pallet shrink wrap machine, it is essential to perform a thorough cost-benefit analysis. The initial expenditure may appear daunting, especially for smaller businesses. However, evaluating the long-term benefits reveals that these machines can significantly enhance packaging efficiency, protect goods during transit, and reduce labor costs associated with manual wrapping processes. By automating the wrapping system, businesses can save time and ensure uniformity in packaging, resulting in fewer errors and reduced material waste.

Moreover, investing in shrink wrap equipment can lead to substantial improvements in product presentation and customer satisfaction. A well-wrapped product not only reduces the risk of damage but also conveys a professional image to customers. The durability of shrink wrap protects items from environmental factors, which can reduce the likelihood of returns due to damaged goods. Over time, the savings accrued from decreased labor costs, increased productivity, and minimized damage can greatly outweigh the initial investment, making the purchase of a pallet shrink wrap machine a financially sound decision for businesses aiming to grow and streamline their operations.

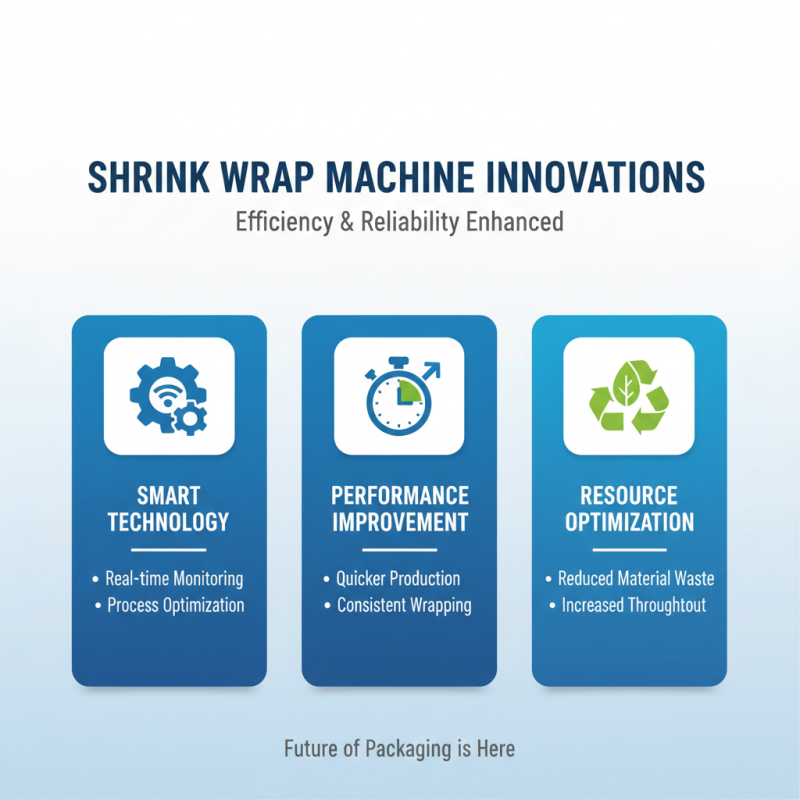

Industry Trends: Shrink Wrap Machine Performance Metrics and Innovations

In recent years, the shrink wrap machine industry has seen significant advancements that focus on enhancing performance metrics for efficiency and reliability. Modern machines are now equipped with smart technology that enables real-time monitoring of wrapping processes, helping businesses optimize their operations. These innovations allow for quicker production times and improved wrapping consistency, which are essential for reducing material waste and increasing overall throughput.

Additionally, energy efficiency has become a pivotal aspect of shrink wrap machine design. Many manufacturers prioritize sustainability by creating machines that consume less power without compromising on performance. This trend not only lowers operational costs but also aligns with growing environmental concerns among consumers and businesses alike. Moreover, the integration of user-friendly interfaces has simplified the setup and operation of these machines, making it easier for employees to adapt and maintain efficiency levels in their workflow. As such, businesses seeking to choose the best pallet shrink wrap machine must focus on these evolving performance metrics and innovations to meet their specific needs effectively.

Related Posts

-

Top 10 Tips for Choosing the Best Pallet Shrink Wrap Machine for Your Business

-

What is an Automatic Pallet Wrapping Machine and How Does It Work?

-

How to Choose the Best Air Pillow Machine for Your Packaging Needs

-

Top 10 Benefits of Using a Plastic Strapping Machine for Packaging Solutions

-

Best Air Cushion Machine for Optimal Packaging Efficiency and Cost Savings

-

Top 10 Tips for Choosing the Best Box Taping Machine for Your Needs