How to Choose the Best Shrink Wrap Machine for Your Business Needs

Choosing the right shrink wrap machine is crucial for your business. It can influence efficiency and product presentation. An ideal machine ensures protection, enhances appearance, and optimizes resources.

When selecting a shrink wrap machine, consider your product size and type. Machines vary greatly in their specifications, making it vital to match your needs to their capabilities. Think about the volume of packaging you require. High-output machines might seem appealing but can be costly and complex.

Reflect on your workspace too. A bulky machine may not fit well in smaller areas. Maintenance is another factor. Some machines require more attention than others. Balancing these aspects can lead to better decision-making. Ultimately, the right shrink wrap machine should elevate your packaging efforts while being practical for your business.

Understanding Different Types of Shrink Wrap Machines Available Today

When selecting a shrink wrap machine, understanding the types available is essential. There are several key options on the market today. The most common types include manual, semi-automatic, and fully automatic machines. Manual machines require the user to operate the entire process by hand. They are cost-effective but can be labor-intensive. In contrast, semi-automatic machines automate some steps, making them faster and easier to use. Fully automatic machines offer high efficiency, with minimal human intervention. Industry reports indicate that the demand for fully automatic machines has steadily increased, reflecting a shift toward automation in packaging processes.

When evaluating your options, consider the scale of your business. Smaller operations might benefit from manual machines. However, as production needs grow, investing in semi-automatic or fully automatic models becomes crucial. Look for machines that can accommodate various product sizes and shapes. It’s important to assess the operating speed, as some machines can wrap products up to 30 packages per minute.

Tips: Always check for reliability and maintenance requirements before purchasing. Seek machines that are durable and easy to repair. Keep in mind that high-volume production can lead to wear and tear, which may increase costs if the machine requires frequent servicing. Do thorough research and reflect deeply on your actual needs to avoid overspending.

How to Choose the Best Shrink Wrap Machine for Your Business Needs

| Machine Type | Best For | Speed (Packages/Min) | Price Range ($) | Key Features |

|---|---|---|---|---|

| Semi-Automatic | Small to Medium Businesses | 10-20 | 2,000 - 5,000 | Easy operation, moderate speed, affordable |

| Automatic | Large Scale Production | 30-50 | 10,000 - 30,000 | High speed, continuous operation, advanced features |

| L-Sealer | Versatile Packaging Needs | 10-15 | 3,000 - 7,000 | Flexible film options, compact design |

| Shrink Tunnel | High Volume Shrink Wrapping | 40-100 | 5,000 - 25,000 | Efficient heat distribution, large capacity |

Evaluating Your Production Volume and Packaging Speeds Requirements

When evaluating production volume and packaging speed requirements, it’s essential to know your business needs. Understanding your output levels directly influences your equipment selection. For small operations, a manual machine might suffice. However, larger companies could require automated systems to keep up with demand. Statistics show that companies using high-speed shrink wrap machines can increase productivity by up to 50%.

Consider how many products you package daily. If your production volume exceeds 2,000 units, automating your shrink wrap process makes sense. This shift can save both time and labor costs. Machines with variable speed settings allow you to adjust based on different products, which is crucial for efficiency.

Tip: Regularly assess your production flow. If bottlenecks occur, it may be time for an upgrade. Also, invest in training for staff. Understanding machine capabilities can lead to significant efficiency gains. An ongoing evaluation of your packaging needs ensures you invest in the right equipment, catering perfectly to your operational demands.

Analyzing Film Compatibility and Material Specifications for Optimal Performance

When choosing a shrink wrap machine, analyzing film compatibility is crucial. Different films serve unique purposes. For instance, PVC and polyolefin have varying shrink rates and clarity. Some films stretch better but may not seal properly. This can affect the overall packaging quality.

Material specifications also play a significant role. Consider the thickness and gauge of the film. Thicker films are durable but may require more power and time to shrink. The type of items being wrapped matters too. Fragile items need a gentler approach. If the film is too tight, it can damage the product.

Balancing these factors is not always straightforward. You may encounter challenges in selecting the right combination. Test different films and machines before making a final decision. The learning curve can lead to mistakes, but it’s part of the process. Always evaluate your choices based on performance and cost-effectiveness. Trial and error will guide you toward the best solution for your business.

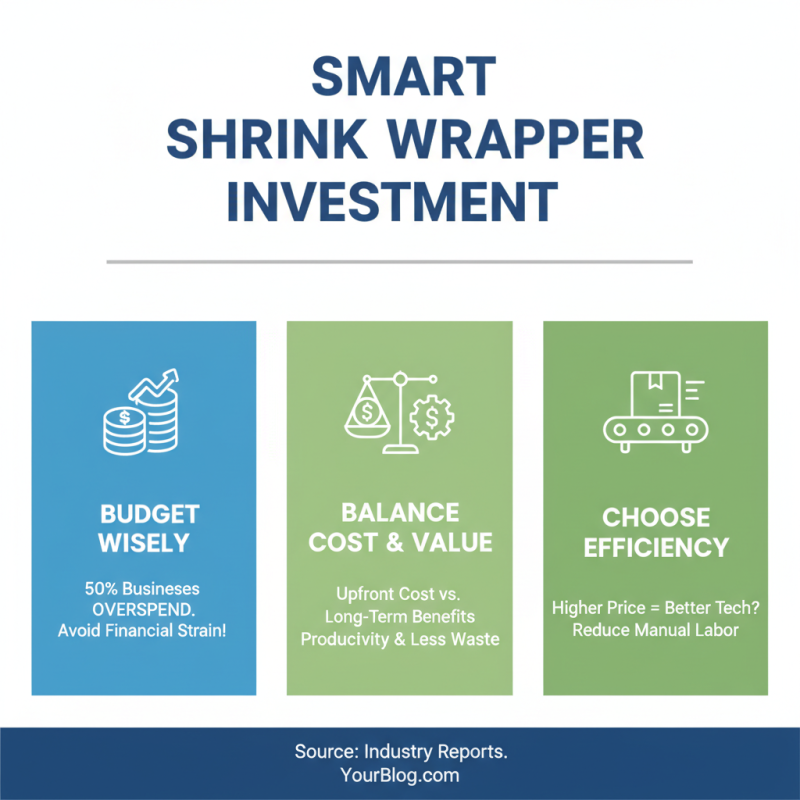

Assessing Budget Constraints and Long-Term Investment Benefits

When choosing a shrink wrap machine, consider your budget closely. A common mistake businesses make is overspending. According to industry reports, 50% of small businesses exceed their original equipment budget. This can lead to financial strain. It's essential to balance your immediate financial constraints with potential long-term benefits. A higher upfront cost may yield better productivity and reduce waste in the long run.

Tips: Calculate your average packaging volume. This can help identify the size and type of machine needed. Don’t overlook maintenance costs, either. Machines that require high maintenance might save money now, but could cost more later.

Consider the features that matter most. Automated systems have higher initial costs but can significantly save labor costs. IQF data projects that automation in packaging could reduce labor needs by up to 30%. Still, contemplate the learning curve involved with new technology; it may impact operations initially. Always factor in training costs as you assess your investment.

Considering Space and Ergonomics in Your Packaging Facility Design

Designing a packaging facility involves careful consideration of space and ergonomics. The layout should facilitate smooth workflows while ensuring that employees can operate with ease. An efficient design minimizes unnecessary movements. Workers can get frustrated if they have to navigate tight spaces or reach for materials that are too far away.

When selecting a shrink wrap machine, think about its placement. A machine that is too big or awkward can consume valuable floor space. However, if it's too compact, it may slow down operations. Consider using movable equipment to adapt to changing needs. This flexibility can improve overall efficiency.

Ergonomics play a crucial role in worker comfort. Machines should be at the right height, reducing strain on the back and arms. Easy access to supplies can speed up the packaging process. Sometimes, companies overlook these factors, leading to employee fatigue. Addressing spatial design and ergonomic concerns can greatly enhance productivity and worker satisfaction.

Related Posts

-

Top 10 Benefits of Using a Plastic Strapping Machine for Packaging Solutions

-

Why You Need a Plastic Banding Machine for Your Packaging Operations

-

How to Choose the Best Automatic Pallet Wrapping Machine for Your Business

-

Top 10 Tips for Choosing the Best Box Taping Machine for Your Needs

-

Top 10 Benefits of Using Automatic Stretch Wrap Machines for Your Business

-

Best Air Cushion Machine for Optimal Packaging Efficiency and Cost Savings