Essential Tips for Choosing the Best Automatic Banding Machine for Your Business

In the fast-paced world of packaging and logistics, the choice of an automatic banding machine can significantly affect efficiency and productivity. According to industry expert John Smith, "Selecting the right automatic banding machine is not just about the price; it's about finding the right fit for your business needs." This statement underscores the importance of understanding various factors when investing in such equipment.

When considering an automatic banding machine, businesses must evaluate their specific requirements, including speed, flexibility, and compatibility with existing systems. Additionally, factors such as maintenance, support, and ease of operation are crucial in ensuring that the machine integrates smoothly into production lines.

Ultimately, making an informed decision will lead to enhanced operational efficiency and a better bottom line. By prioritizing the right features and performance metrics, companies can leverage the capabilities of an automatic banding machine to improve their packaging processes and meet customer demands effectively.

Essential Considerations for Selecting an Automatic Banding Machine

When selecting an automatic banding machine for your business, several essential considerations come into play to ensure you make the right choice. First and foremost, assess the specific needs of your operation. Different industries may have distinct requirements concerning the types of products being banded, the size of materials, and the desired speed of production. Understanding your operational demands will help you identify a machine that can efficiently meet your throughput goals while maintaining the quality of the banding.

Another critical factor is the machine's adaptability and user-friendliness. Choose a model that offers flexibility in terms of banding material and size adjustments to accommodate various products. Additionally, ease of use and maintenance should be prioritized; machines that are complicated to operate or require excessive upkeep can lead to downtime and increased labor costs. Look for automation features that minimize manual intervention while enhancing the consistency and precision of the banding process. Reliability and durability are also paramount, as investing in a robust machine will maximize efficiency and reduce the frequency of repairs or replacements.

Essential Tips for Choosing the Best Automatic Banding Machine for Your Business

| Feature | Description | Consideration |

|---|---|---|

| Speed | Measured in bands per minute, indicating how fast the machine can operate. | Choose a speed that fits your production needs to maximize efficiency. |

| Material Compatibility | Types of materials the machine can work with, such as plastic, paper, or metal bands. | Ensure the machine supports the specific materials used in your packaging process. |

| Adjustability | Ability to adjust banding size and tension settings easily. | Look for machines that allow for quick adjustments to accommodate different products. |

| Ease of Use | User-friendly controls and interface for quick setup and operation. | Select a model that minimizes training time for operators. |

| Maintenance Requirements | Level of maintenance needed to ensure optimal performance and longevity. | Opt for machines that are easy to maintain and support long-term use. |

| Warranty and Support | Length and type of warranty provided and the availability of technical support. | Select a manufacturer who offers reliable support and a strong warranty. |

Key Features to Look for in Automatic Banding Machines in 2023

When selecting an automatic banding machine for your business in 2023, there are several key features to consider to ensure optimal performance and efficiency. First and foremost, assess the machine's speed and efficiency. A high-speed banding machine can significantly enhance productivity, especially if your operation demands quick turnaround times. Additionally, look for adjustable settings that can accommodate various packaging sizes and materials, allowing for versatile use across different products.

Another essential feature is the ease of operation and maintenance. Choose a machine designed with user-friendly controls and clear interfaces. This can help minimize training time for your staff and reduce the likelihood of operational errors. Moreover, consider machines with low maintenance requirements, which can save you time and costs in the long run.

Tips to remember: Always check the durability of the construction materials, as a sturdy design will withstand the rigors of daily use. Furthermore, consider technology integration, such as connectivity options for tracking and monitoring banding operations, which can provide insights for improving logistics and inventory management. By focusing on these features, you can select the best automatic banding machine to meet your business needs.

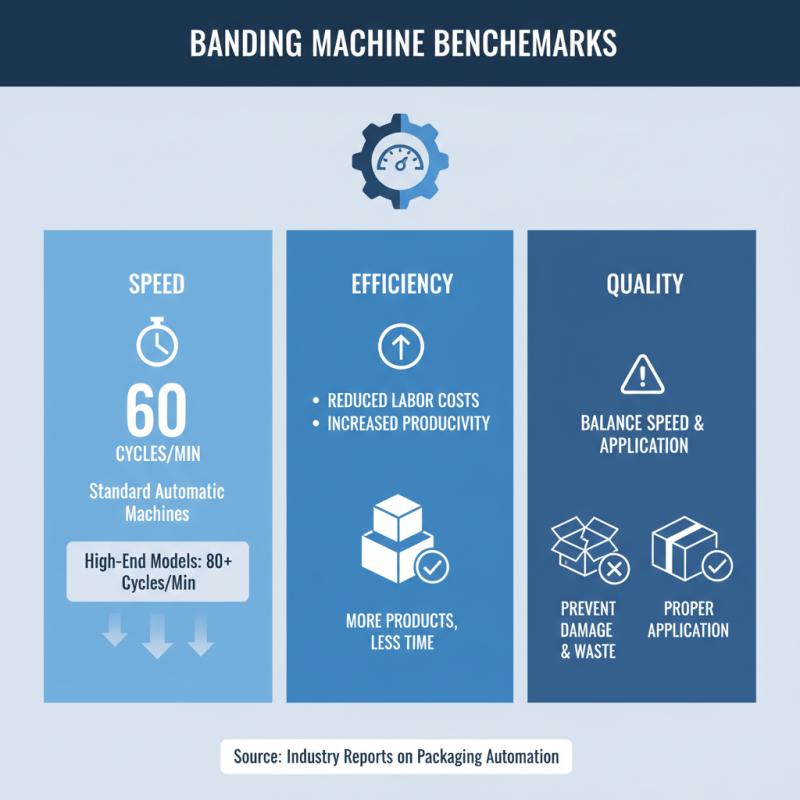

Evaluating Banding Speed and Efficiency: Industry Benchmarks

When evaluating banding machines for your business, understanding the benchmarks for banding speed and efficiency is crucial. Industry reports indicate that modern automatic banding machines can achieve speeds of up to 60 cycles per minute, with some high-end models reaching even higher rates. This speed significantly reduces labor costs and enhances productivity, allowing businesses to package more products in less time. However, it's important to balance speed with the quality of the banding process, as improper application can lead to product damage and increased waste.

Efficiency in banding is also measured by the machine's ability to minimize downtime and ensure consistent performance. According to a recent analysis, the optimal efficiency rate for automatic banding machines is around 95%. This means that the machine should operate at or near its maximum capacity with minimal interruptions due to jams or malfunctions. Investing in a machine that has been recognized for its reliability and streamlined operation can lead to a significant improvement in your production line's overall efficiency. By focusing on these benchmarks, you can make a more informed decision that aligns with your operational goals.

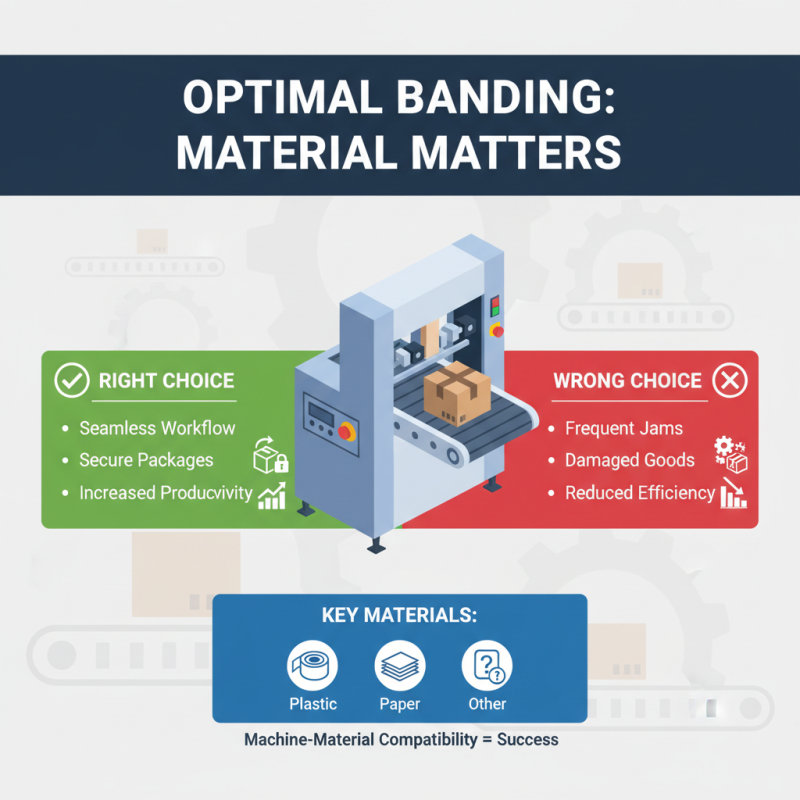

Importance of Banding Material Compatibility in Your Business Operations

When selecting an automatic banding machine for your business, understanding the importance of banding material compatibility is crucial. The right banding material not only ensures the integrity of your packaged goods but also affects operational efficiency. Using incompatible materials can lead to frequent jams, reduced productivity, and even damage to the items being banded. To maintain a seamless workflow, it's essential to choose a machine that is designed to work with the specific types of banding materials you intend to use, whether they're plastic, paper, or other materials.

Tips for choosing the right machine include assessing the material thickness and width compatibility with the banding machine. Make sure to verify that the machine you select can accommodate the specific dimensions of the banding material you plan to utilize. Additionally, consider the environmental conditions under which the banding will occur. For instance, if your products are likely to face humidity or temperature variations, ensure the banding material can withstand such factors to maintain its effectiveness.

Furthermore, evaluate the type of items you'll be banding. Heavy or irregularly shaped products will require a more robust banding solution, thus necessitating the selection of appropriate materials. By prioritizing material compatibility, you can significantly enhance your production efficiency and protect your products during transportation and storage, ultimately leading to a more successful operation.

Cost Analysis: Long-Term Savings with Automatic Banding Machines

When considering the investment in an automatic banding machine, a thorough cost analysis is essential to uncover the long-term savings it can provide for your business. While the initial purchase price may seem substantial, analyzing the operational efficiencies gained can significantly offset these costs. Automatic banding machines streamline the packaging process, reducing the labor needed for manual banding. This efficiency not only translates to lower labor costs but also allows employees to redirect their efforts towards more strategic tasks within the operation.

Moreover, the durability and reliability of automatic banding machines contribute to long-term savings. These machines are designed for high-volume operations, minimizing downtime and maintenance costs compared to manual banding methods. Additionally, they typically use materials more effectively, reducing waste and ensuring that packaging materials are utilized optimally. Consequently, businesses can enjoy enhanced throughput and a more environmentally sustainable operation, solidifying the overall financial benefits of incorporating an automatic banding machine into their production line.

Related Posts

-

What is an Automatic Pallet Wrapping Machine and How Does It Work?

-

Top 10 Tips for Choosing the Best Pallet Shrink Wrap Machine for Your Business

-

Top 10 Tips for Choosing the Best Box Taping Machine for Your Needs

-

How to Choose the Best Air Pillow Machine for Your Packaging Needs

-

Best Air Cushion Machine for Optimal Packaging Efficiency and Cost Savings

-

Top 10 Benefits of Using a Plastic Strapping Machine for Packaging Solutions