Top 10 Tips for Choosing the Best Box Taping Machine for Your Needs

In today’s fast-paced packaging industry, the importance of selecting the right box taping machine cannot be overstated. According to a recent report by Packaging Strategies, the global market for box taping machines is projected to reach $1.5 billion by 2025, reflecting a compound annual growth rate of 5.7%. This growth underscores the necessity for businesses to invest in equipment that enhances operational efficiency and meets their specific packaging needs. Choosing the ideal box taping machine ensures not only cost-effectiveness but also significant improvements in productivity.

Industry expert Jacob Thompson, a senior analyst at Automation Insights, emphasizes the impact of proper machine selection on business operations: "A box taping machine tailored to your production requirements can dramatically reduce labor costs and improve packaging speed." As companies scale their operations, understanding the myriad options available—from manual to fully automated machines—becomes crucial. This guide aims to equip professionals with the top ten tips for selecting the best box taping machine, ensuring that they make informed decisions that align with their operational goals and budget constraints.

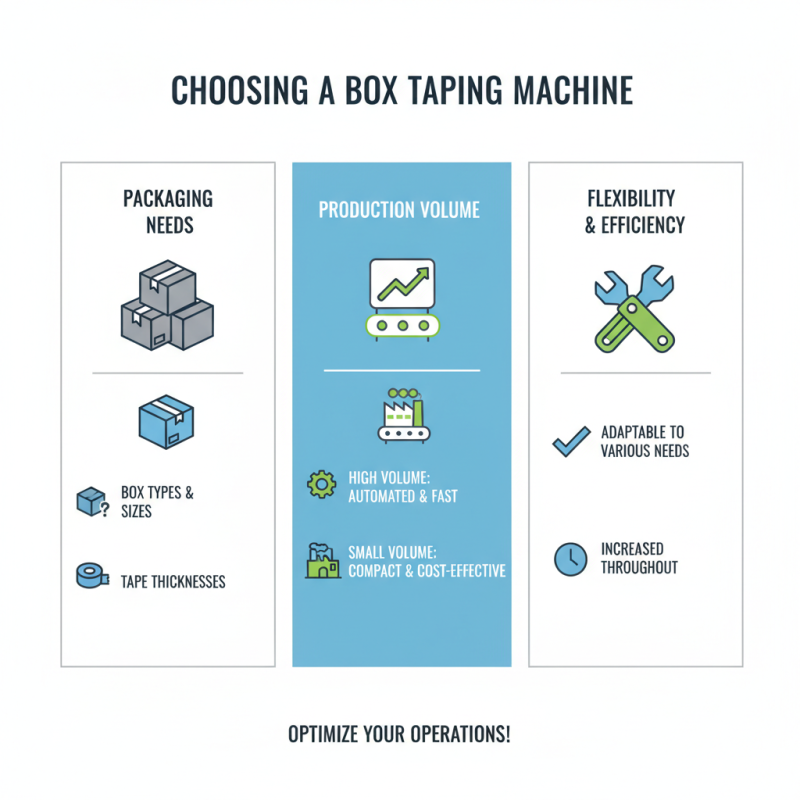

Understanding Your Packaging Needs for Box Taping Machines

When choosing a box taping machine, understanding your packaging needs is crucial. Consider the types of materials you'll be working with, such as corrugated boxes, and the dimensions of those boxes. A machine that accommodates various box sizes and can handle different tape thicknesses will provide you with greater flexibility in your operations. Additionally, analyze the production volume: a high-volume operation may require a faster, more automated machine, while a smaller business might benefit from a more compact and cost-effective option.

Another important aspect to consider is the environment in which the machine will be used. If you work in a humid or dusty environment, it’s essential to select a taping machine that can withstand these conditions. Durability and maintenance needs are also key factors; opt for a machine that can deliver consistent performance without frequent service interruptions. Remember to evaluate your budget too, as this will guide you toward machines that offer the best value without compromising on quality.

When assessing your needs, here are some quick tips: First, consider whether you prioritize speed or precision in your packaging workflow. Second, evaluate whether your operation requires manual, semi-automatic, or fully automatic systems based on your staffing and workflow efficiency. Lastly, think about future needs; investing in a versatile machine today can save you time and money down the road as your business grows.

Evaluating Different Types of Box Taping Machines Available

When evaluating different types of box taping machines available on the market, it's crucial to consider the specific needs of your operation. There are generally three categories of machines: manual, semi-automatic, and fully automatic.

Manual taping machines are ideal for smaller operations where volume is limited and flexibility is key. They offer simplicity and require minimal investment, making them a great choice for businesses that tape boxes sporadically.

On the other hand, semi-automatic and fully automatic machines are designed for higher volume operations. Semi-automatic machines still require some manual intervention, providing a balance between efficiency and control. They are suitable for businesses that have a steady flow of boxes but may not need the full automation offered by their fully automatic counterparts.

Fully automatic box taping machines, in contrast, are designed for heavy-duty use, capable of taping boxes at a rapid pace without operator input. These machines are best suited for large warehouses or production facilities where high efficiency and throughput are paramount.

Assessing Tape Specifications for Optimal Performance

When selecting a box taping machine, one of the most critical aspects to consider is the tape specifications, which can significantly influence the efficiency and effectiveness of your packaging operations. The thickness, adhesive quality, and material composition of the tape are crucial parameters that directly impact the machine's performance. For instance, a thicker tape often provides better sealing capabilities, making it ideal for heavier packages. Conversely, a thinner tape can be more suitable for lighter items, allowing for faster application speeds without compromising the integrity of the seal.

Additionally, evaluating the adhesive type of the tape is essential. Pressure-sensitive adhesives are widely used due to their ease of application and effectiveness in various temperature conditions. On the other hand, hot-melt adhesives may offer superior bonding strength, making them ideal for demands in high-stress packaging environments. Furthermore, considering the compatibility of the tape with the machine's application mechanisms is vital. Ensuring that the tape unwinds smoothly and adheres properly minimizes downtime and maximizes productivity, helping to streamline your packing process. Balancing these tape specifications with your operational requirements will ensure you select a taping machine that meets your specific needs efficiently.

Top 10 Tape Specifications for Box Taping Machines

This chart illustrates key specifications to consider when selecting a box taping machine, including adhesive strength, backer thickness, roll length, tensile strength, and temperature resistance.

Key Features to Look for in a Box Taping Machine

When choosing a box taping machine, it is crucial to consider several key features that will enhance efficiency and meet your specific packaging needs. First and foremost, the tape width compatibility is an essential factor. A machine that accommodates various tape sizes allows for flexibility, enabling you to work with different box dimensions and styles without constantly switching machines. Additionally, look for machines that offer adjustable tape tension settings. Proper tension ensures that the tape adheres securely, preventing packages from coming undone during transit.

Another important feature to examine is the ease of operation. User-friendly controls and quick-change capabilities can significantly reduce downtime, optimizing your workflow. Look for machines with automatic or semi-automatic functionality that can streamline the taping process. Furthermore, the durability and build quality of the machine are vital for long-term use. A robust design will withstand the rigors of daily operations, providing reliability as your packaging needs evolve. Consideration of these features will help ensure you choose a box taping machine that not only meets your immediate requirements but also adapts to future demands.

Top 10 Tips for Choosing the Best Box Taping Machine for Your Needs - Key Features to Look for in a Box Taping Machine

| Feature | Importance | Recommended Options |

|---|---|---|

| Type of Tape | Essential for product compatibility | Acrylic, Hot Melt, Water Activated |

| Speed | Higher speed increases productivity | 20-60 boxes/minute |

| Adjustability | Accommodates various box sizes | Manual vs. Automatic adjustments |

| Durability | Long-lasting investment | Metal vs. Plastic construction |

| Ease of Use | Minimizes training time | User-friendly controls |

| Maintenance Requirements | Reduces downtime | Easy access for servicing |

| Safety Features | Protects operators | Guardrails, emergency stops |

| Cost | Fits your budget while meeting needs | Price range options |

| Manufacturer Support | Helps with issues and queries | Warranty and customer service quality |

| Reviews and Recommendations | Insights from experienced users | Look for testimonials and ratings |

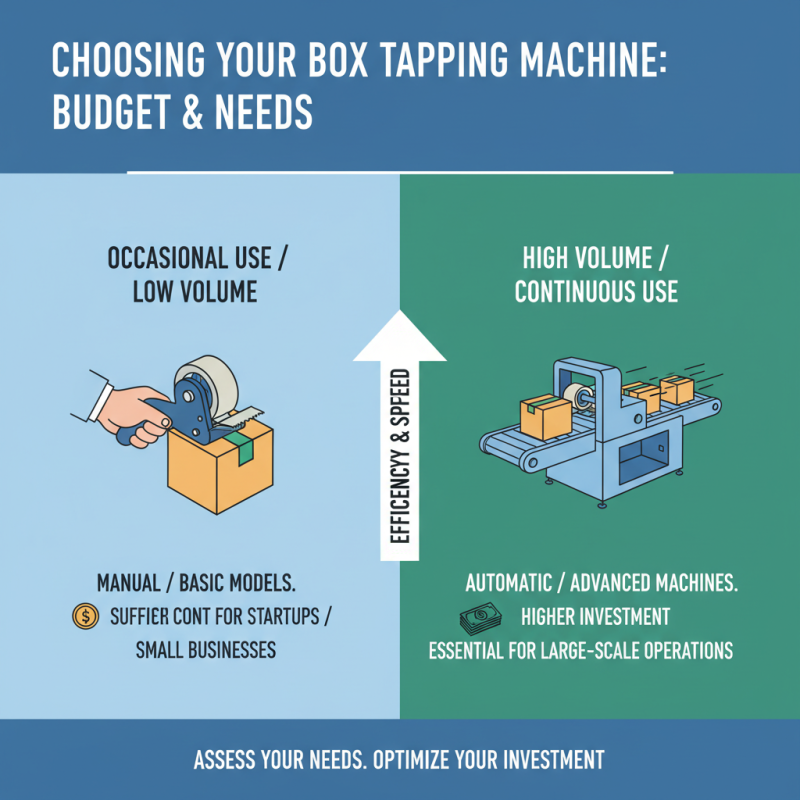

Budget Considerations When Choosing a Box Taping Machine

When selecting the ideal box taping machine, one of the key factors to consider is your budget. The market offers a wide range of options, from basic manual models to more advanced automatic machines, each with varying price points. It’s essential to assess your operational needs and determine how much you can allocate for this investment. A lower-cost option might be sufficient for occasional use, while a higher-end model could be necessary for high-volume operations where efficiency and speed are crucial.

Additionally, it’s vital to analyze the long-term costs associated with each option. Some machines may have a lower initial purchase price but can incur higher maintenance or material expenses over time. Conversely, investing in a more robust machine can lead to savings by reducing tape waste and enhancing throughput. Careful consideration of these factors will not only help you find a box taping machine that meets your needs but also ensures that you stay within your budget while optimizing productivity.