How to Choose the Right Heat Shrink Machine for Your Needs?

Choosing the right heat shrink machine can seem daunting. Many options exist, each with unique features. Understanding your specific needs is crucial.

Heat shrink machines vary in size and efficiency. Some are designed for high-volume production. Others cater to smaller, more specialized tasks. Consider the type of materials you will be using. It’s essential to match the machine to your application.

Price is another critical factor. A more expensive machine may offer added features, but will it meet your requirements? Reflect on your budget. Sometimes, a less costly option can work just as well. Take your time to evaluate your choices carefully. The right decision can lead to increased productivity and reduced waste.

Understanding Your Heat Shrink Application Requirements

Choosing the right heat shrink machine begins with understanding your specific application requirements. What materials will you be working with? Different plastics shrink at varying temperatures. Knowing the type of shrink film you’re using can greatly influence your choice.

Consider the volume of production. Are you running a small workshop or a larger manufacturing facility? Machines vary in size and output speed. A small machine might suffice for limited runs. But if you anticipate high volumes, a more robust model could save you time.

Think about the features you might need. Some machines have adjustable temperature settings. Others allow for various film sizes. Not every feature is essential for your needs. Sometimes, simplicity is key. Reflect on what you truly require and avoid over-complicating your decision. This process may take time, but it is crucial.

Types of Heat Shrink Machines: An Overview

When considering heat shrink machines, it's essential to understand the different types available. There are three main categories: manual, semi-automatic, and fully automatic. Manual machines require operator involvement. This may lead to inconsistencies in production. Semi-automatic machines offer increased efficiency but still need supervision. Fully automatic machines, however, can dramatically reduce labor costs. According to industry reports, the demand for fully automatic machines is increasing by 15% each year.

Each type of machine serves distinct purposes. Manual machines are best for low-volume tasks. They are typically less expensive and simple to operate. For mid-range production, semi-automatic machines can be effective. They provide a balance between cost and efficiency. Fully automatic machines are ideal for high-volume operations. They can handle intricate tasks with minimal human intervention.

Making the right choice depends on production needs and budget. Understand your specific requirements. A mismatch between machine type and usage can cause inefficiencies. An analysis of workflow can reveal where improvements are needed. This ensures you invest in the right machine type. Data suggests that up to 40% of businesses may not utilize their machines to full capacity. Adjustments are often necessary to optimize performance.

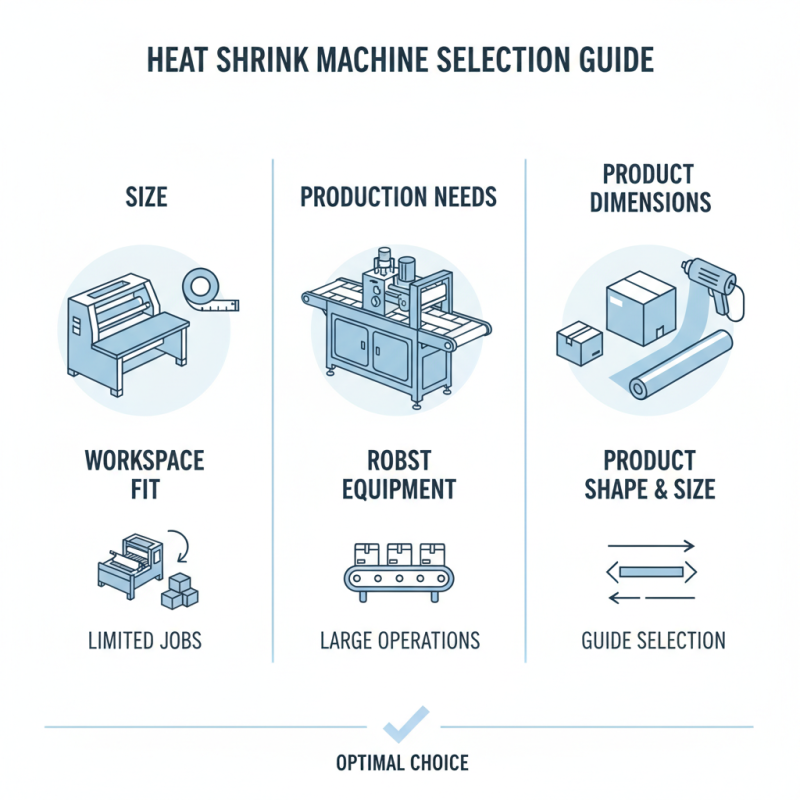

Key Features to Consider When Selecting a Heat Shrink Machine

When choosing a heat shrink machine, several key features come into play. Size is crucial. A machine that fits your workspace is better than one that doesn’t. Think about your production needs. A smaller machine might suffice for limited jobs, but larger operations require robust equipment. The dimension of products to be shrunk should also guide your selection.

Speed is another essential factor. Look for machines with adjustable settings. This flexibility allows you to manage different items efficiently. Consider the heat source, whether it's electric or gas. Each has its advantages, depending on your work environment. Airflow is important, too. Proper airflow ensures even shrinking, which can be a challenge with some models.

Lastly, don’t overlook user-friendliness. Complicated controls can hinder operation and lead to errors. A machine that is easy to operate saves time and minimizes mistakes. Always read reviews before making a decision. Remember, finding the right machine might take time. Evaluate your options and reflect on your specific needs.

Assessing Your Budget and Cost-Effectiveness

When selecting a heat shrink machine, budget should be a primary concern. Determine your financial limits early on. A machine's price can widely vary based on its features and capacity. It's crucial to match your needs with your budget. The upfront cost is just one aspect. Consider long-term operational expenses too.

Cost-effectiveness is about more than just the price tag. Analyze how often you'll use the machine. A higher-priced model may offer better longevity or efficiency. This could lead to savings over time. Don’t overlook maintenance costs, as those can add up. Take the time to research models that balance quality and affordability.

Sometimes, it’s tempting to opt for the cheapest option. But this can result in frequent repairs or poor performance. Reflect on the trade-offs between cost and quality. A machine that breaks down often will cost more in the long run. Focus on finding the right machine that aligns with your production needs and budget constraints.

How to Choose the Right Heat Shrink Machine for Your Needs? - Assessing Your Budget and Cost-Effectiveness

| Machine Type | Features | Max Shrink Size | Speed (units/hour) | Cost ($) | Cost-Effectiveness Rating |

|---|---|---|---|---|---|

| Standard Heat Shrink Machine | Manual operation, adjustable temperature | 150 mm | 50 | 300 | Good |

| Automatic Heat Shrink Tunnel | High efficiency, programmable settings | 250 mm | 200 | 800 | Excellent |

| Portable Heat Shrink Gun | Compact, lightweight, ideal for small jobs | 100 mm | 30 | 50 | Fair |

| Industrial Heat Shrink Machine | Heavy-duty, high output, automated | 500 mm | 500 | 1500 | Outstanding |

Maintenance and Support: Ensuring Longevity of Your Equipment

Maintaining a heat shrink machine is crucial for ensuring its longevity and efficiency. Regular maintenance can prevent unexpected breakdowns. According to industry studies, nearly 30% of equipment failures are due to insufficient maintenance. Regular inspections, cleaning, and timely part replacements can drastically reduce these failures. It's essential to follow the manufacturer's guidelines closely, as neglecting them can lead to premature wear.

Additionally, support from knowledgeable technicians can enhance the machine's lifespan. Studies show that machines with regular professional check-ups last up to 20% longer. Technicians can spot potential issues before they escalate. Having a proactive approach to maintenance is vital, yet many operators overlook this aspect. They often wait for problems to occur rather than addressing them early.

It's also important to keep a detailed maintenance log. This practice can reveal patterns that indicate when parts might need replacement. However, some operators may be hesitant to create such logs due to perceived complexities. In reality, a simple checklist can facilitate this process. Over time, maintaining accurate records aids in making informed decisions about equipment upgrades and replacements.

Heat Shrink Machine Usage and Maintenance Overview

Related Posts

-

How to Choose the Best Automatic Pallet Wrapping Machine for Your Business

-

How to Choose the Best Air Pillow Machine for Your Packaging Needs

-

Top 10 Tips for Choosing the Best Pallet Shrink Wrap Machine for Your Business

-

Semi Automatic Strapping Machine Tips for Optimal Performance?

-

2026 Top Packaging Machine Innovations to Watch for Future Trends?

-

Why You Need a Plastic Banding Machine for Your Packaging Operations