Why You Need a Plastic Banding Machine for Your Packaging Operations

In today's fast-paced industrial landscape, efficient packaging operations are crucial for businesses aiming to maximize productivity and reduce costs. One innovative solution that has emerged to address these challenges is the plastic banding machine. This advanced equipment not only enhances the packaging process but also ensures that products are securely bundled for transport, minimizing the risk of damage and loss. As companies strive to meet increasing market demands, investing in a plastic banding machine can be a game-changer.

The versatility and effectiveness of plastic banding machines are transforming how businesses approach their packaging needs. They enable a wide range of industries to automate their bundling processes, offering a reliable and cost-effective method for securing products. By utilizing a plastic banding machine, companies can streamline their operations, allowing for quicker turnaround times and greater efficiency. Furthermore, with the ability to adjust tension and material sizes, these machines cater to various packaging requirements, making them an indispensable asset in modern packaging operations.

Ultimately, the integration of a plastic banding machine into packaging workflows not only enhances operational efficiency but also supports sustainability efforts. As businesses work to adopt smarter, eco-friendly practices, utilizing plastic banding can reduce material waste while maintaining the integrity of packaged goods. Embracing this technology is not just about keeping up with industry trends; it is about positioning your business for success in a competitive marketplace.

The Importance of Packaging Efficiency in Modern Operations

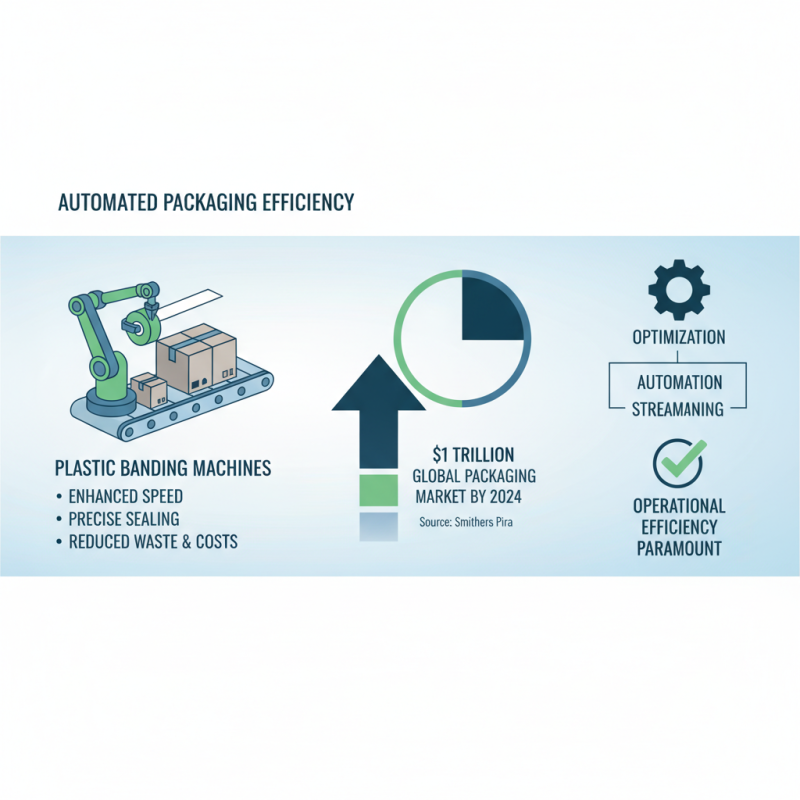

In the competitive landscape of modern packaging operations, efficiency is paramount. Companies are increasingly seeking ways to optimize their processes, reflecting a growing trend towards automating and streamlining packaging operations. According to a study by Smithers Pira, the global packaging market is projected to grow to $1 trillion by 2024, highlighting the importance of innovative solutions like plastic banding machines in maintaining operational efficiency. These machines not only enhance speed but also ensure precise sealing, reducing material waste and operational costs.

To maximize the benefits of packaging efficiency, businesses should consider the integration of plastic banding machines into their workflows. These devices can significantly reduce labor costs by automating the banding process, allowing employees to focus on higher-value tasks. Additionally, implementation of such machines can lead to a reduction in packaging time by up to 30%, as reported by Packaging Strategies, which directly translates into increased throughput and customer satisfaction.

Tips: When selecting a plastic banding machine, evaluate the machine's versatility to accommodate various packaging sizes and materials. Regular maintenance is also crucial; scheduling periodic checks can prevent downtime and prolong the machine's lifespan. Finally, ensure that there is adequate training for operators to maximize the efficiency of the equipment. By prioritizing these aspects, companies can enhance their packaging efficiency and stay competitive in a rapidly evolving market.

Understanding Plastic Banding Machines and Their Functionality

Plastic banding machines are specialized equipment designed to apply plastic straps around products or packages, securing them together and providing stability during transportation and storage. These machines operate by automatically feeding, tensioning, and sealing the strap, ensuring a tight and durable hold. This process not only speeds up packaging operations but also enhances the overall efficiency of the supply chain, reducing labor costs and minimizing the risk of product damage.

In addition to enhancing workflow, plastic banding machines offer versatility in packaging various types of products, from small items to larger bundles. They can accommodate different strap sizes and thicknesses, making them suitable for diverse industries, such as food, electronics, and construction. Moreover, many models are designed with user-friendly interfaces and safety features, enabling operators to work efficiently while minimizing the chances of accidents. Overall, the functionality of plastic banding machines plays a crucial role in ensuring that products remain secure and undamaged as they move along the supply chain.

Plastic Banding Machine Usage in Packaging Operations

Advantages of Using Plastic Banding in Your Packaging Process

Plastic banding has emerged as a favored solution in packaging operations, primarily due to its efficiency and versatility. One of the most significant advantages of using plastic banding is its ability to enhance stability and protection for packaged goods. By securely bundling products together, plastic banding prevents shifting during transportation, reducing the risk of damage. This added layer of security is especially beneficial for fragile items that require careful handling, ensuring that products arrive at their destination in pristine condition.

Moreover, the use of plastic banding can lead to cost savings and increased operational efficiency. Compared to traditional strapping methods, plastic banding offers a lightweight alternative that does not compromise strength. This means lower shipping costs and reduced material expenses, while still maintaining the integrity of the packaging. Additionally, plastic banding machines can automate the strapping process, significantly speeding up production times and allowing staff to focus on other critical aspects of packaging operations. Ultimately, incorporating plastic banding into packaging processes not only streamlines operations but also enhances overall product presentation.

Key Features to Look for in a Plastic Banding Machine

When considering the integration of a plastic banding machine into your packaging operations, it's crucial to focus on the key features that will drive efficiency and productivity. One of the primary attributes to look for is the machine's speed. According to a report from Smithers Pira, the demand for efficient packaging solutions has increased significantly, with a notable trend showing that speed and automation in packaging can boost operational efficiency by up to 30%. A high-speed machine will ensure that products can be banded quickly, reducing bottlenecks in your production line.

Another important feature is adaptability. Ideally, a plastic banding machine should handle various banding materials and sizes to accommodate different product types. The ability to adjust tension settings is also crucial, as improper band tension can lead to product damage or inadequate bundling. A report from Packaging Strategies indicates that 25% of packaging failures are due to inadequate banding, underscoring the importance of precision in this process. Moreover, machines that offer user-friendly interfaces and easy adjustments can significantly enhance operational safety and reduce the risk of human error during high-volume runs.

Lastly, durability and maintenance requirements cannot be overlooked. Machines constructed with robust materials not only provide longevity but also reduce the frequency and costs of repairs. A study published by the International Journal of Packaging Technology found that facilities investing in high-quality equipment experienced a 40% decrease in equipment-related downtime. Considering these features will not only streamline your packaging operations but also ensure higher quality outputs and greater overall satisfaction in the supply chain.

Implementing a Plastic Banding System: Steps and Considerations

Implementing a plastic banding system in your packaging operations can significantly enhance efficiency and product integrity. The first step in this process is choosing the right machine that meets the specific needs of your production line. Consider factors such as the size and weight of the packages, the materials used for banding, and the speed requirements of your operation. A comprehensive evaluation of these elements will ensure that you select a machine capable of optimizing your processes and reducing downtime.

Once the machine is selected, it's important to focus on the integration of the plastic banding system into your current workflow. This involves training staff on how to operate the machine safely and effectively, as well as ensuring that the necessary safety protocols are in place. Additionally, maintenance schedules should be established to prevent any operational hiccups. Communication with your team about the benefits and efficiency gains from the system will foster a smoother transition and enhance overall productivity in your packaging operations.

Why You Need a Plastic Banding Machine for Your Packaging Operations

| Aspect | Details |

|---|---|

| Efficiency | Increases packaging speed by up to 50% compared to manual methods. |

| Cost Savings | Reduces labor costs and material waste, increasing overall ROI. |

| Product Security | Provides a secure and tamper-proof method of packaging goods. |

| Versatility | Can be used for various types of products including boxes, pallets, and bundles. |

| Environmental Impact | Utilizes recyclable materials, contributing to sustainability efforts. |

| Implementation Steps | 1. Assess current packaging processes 2. Choose appropriate machine 3. Train staff 4. Monitor results. |

| Considerations | Budget, space requirements, and integration with existing systems. |

Related Posts

-

Essential Tips for Choosing the Best Automatic Banding Machine for Your Business

-

Best Air Cushion Machine for Optimal Packaging Efficiency and Cost Savings

-

Top 10 Tips for Choosing the Best Box Taping Machine for Your Needs

-

Top 10 Benefits of Using Automatic Stretch Wrap Machines for Your Business

-

How to Choose the Best Air Pillow Machine for Your Packaging Needs

-

Top 10 Benefits of Using a Plastic Strapping Machine for Packaging Solutions