Semi Automatic Strapping Machine Tips for Optimal Performance?

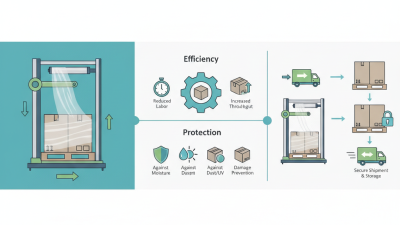

In today's fast-paced packaging environment, the semi automatic strapping machine plays a crucial role. This machine streamlines the strapping process, enhancing efficiency and productivity. However, optimal performance requires more than just basic knowledge.

Understanding the machine's features is essential. Adjusting tension settings can lead to stronger seals, reducing the chances of product damage during transport. Regular maintenance is needed. Dust can build up, leading to unexpected breakdowns. It's a simple task but often overlooked.

Many users find themselves struggling with machine settings. Learning how to adjust for different materials makes a significant difference. A misalignment can lead to improper strapping, resulting in wasted materials. Taking time to study your machine pays off in the long run. Remember, perfect results take practice.

Understanding the Basics of Semi Automatic Strapping Machines

Semi automatic strapping machines are vital in packaging and logistics. They enhance efficiency and reduce labor costs. According to a recent industry report, more than 40% of packaging operations now utilize these machines to streamline their processes.

Understanding the basics can lead to optimal performance. Strapping machines function by applying a strap around products to secure them for shipping. This process can be adjusted—tightness, speed, and type of strap must be matched to the goods. A failure to consider these factors may lead to product damage or inefficient packaging.

Here are some useful tips for performance. Regular maintenance is crucial. Check settings frequently to ensure they fit your products. Misalignment can result in waste and downtime. Also, training staff on machine operations is essential. Employees should be aware of limits and capabilities.

Finally, don’t overlook the importance of strap quality. Using inferior materials can undermine the benefits of a semi automatic machine. Data suggests that 30% of strapping failures come from poor strap selection. Invest time in finding the right materials and settings for your specific needs. This will improve your packaging process significantly.

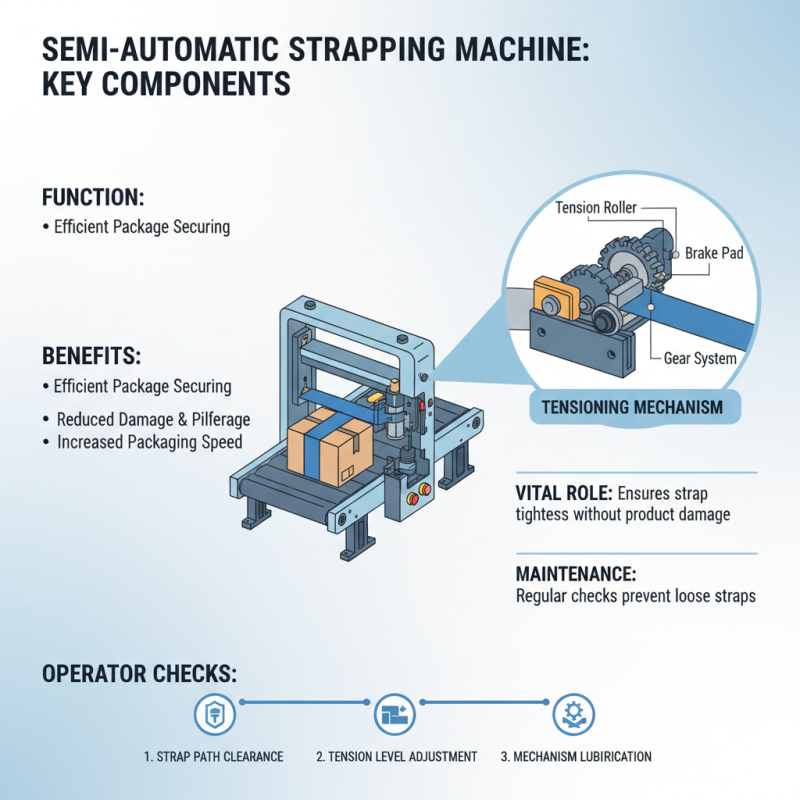

Key Components of Semi Automatic Strapping Machines and Their Functions

Semi-automatic strapping machines are essential tools in packaging. Understanding their key components can help improve their performance. The tensioning mechanism plays a vital role. It ensures the strap is tight enough to secure packages without damaging them. Operators must regularly check this part. If it malfunctions, it can lead to loose straps and damaged goods.

The sealing mechanism is another critical component. It is responsible for joining the ends of the strap securely. A weak seal can cause packages to fall apart. Regular maintenance is crucial here. Inspect the heat blade or seal for wear. Sometimes, operators might overlook this aspect, leading to potential issues.

Lastly, the control panel is essential for ease of operation. It allows users to adjust settings based on the package size. However, it can become confusing. Mistakes in settings can result in inconsistent strapping. Understanding each control button is vital. Improper handling can lead to significant production delays. Keeping the panel clean and intuitive is necessary for optimal performance.

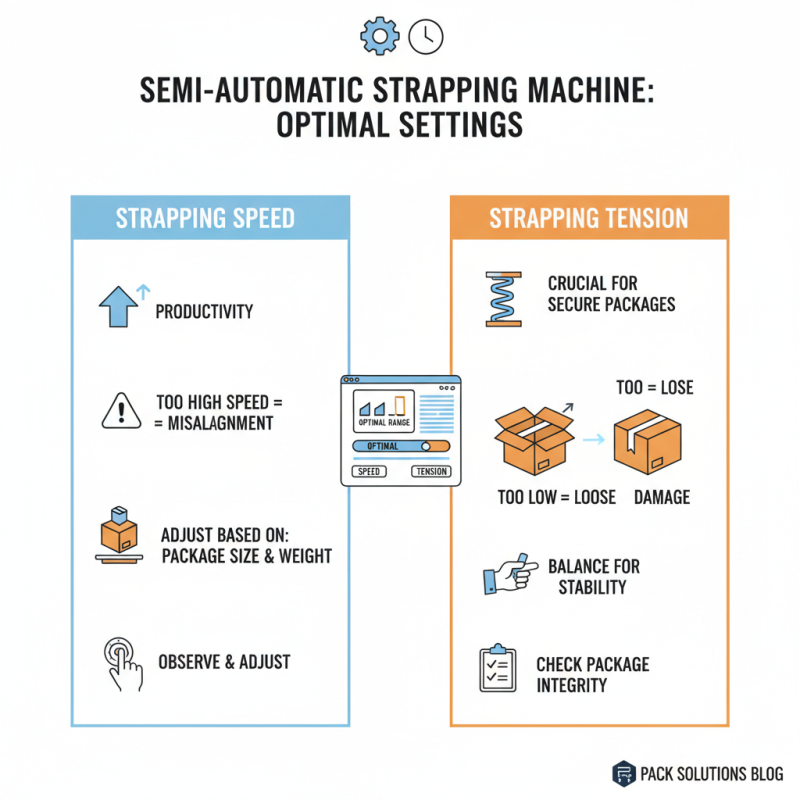

Optimal Settings for Strapping Speed and Tension in Packaging

When using a semi-automatic strapping machine, optimal settings for strapping speed and tension are crucial. The speed of the strapping operation can significantly affect productivity. However, too high a speed may lead to misalignment of packages. Adjust the speed setting based on the size and weight of the items being strapped. Observing how your machine handles various packages will guide your adjustments.

Tension is another critical factor. If the tension is set too high, it may damage the package. Conversely, low tension can result in loose straps. Finding the right balance can take time. Regularly check tension settings, especially with different products. Use test runs to observe how the strapping holds.

Here are a few tips for optimal performance: Always keep the machine clean and well-maintained. Clogged parts can slow down the operation. Check for worn-out components; replacing them when necessary can enhance performance. Additionally, ensure that the strap's quality matches your packaging needs. Consistent inspection will foster a better understanding of the machine's limitations.

Common Maintenance Practices to Enhance Machine Longevity

A well-maintained semi-automatic strapping machine can significantly enhance production efficiency. Regular maintenance practices can extend its lifespan and reduce downtime. Reports indicate that machinery under consistent maintenance performs at optimal levels, with a potential 15-20% increase in output.

Routine checks on wear parts are crucial. Inspect the tensioning system and seals regularly. An overlooked part can lead to costly breakdowns. Keep a maintenance log. This can help track issues and identify patterns. Address them proactively.

Here are a few tips to maintain your strapping machine:

1. Clean the machine daily to remove dust and debris.

2. Lubricate moving parts as per the manufacturer's guidelines.

3. Replace worn-out components promptly to avoid further damage.

Ignoring these practices may result in exceptions, leading to more significant problems later on. An unobserved malfunction can escalate maintenance costs. Remember to observe and improve.

Semi Automatic Strapping Machine Tips for Optimal Performance

| Maintenance Practice | Frequency | Benefits | Estimated Time |

|---|---|---|---|

| Clean the Strapping Machine | Daily | Prevents dust buildup, enhances performance | 15 minutes |

| Lubricate Moving Parts | Weekly | Reduces friction, prevents wear and tear | 10 minutes |

| Inspect Power Supply and Cables | Monthly | Ensures safety and prevents electrical issues | 20 minutes |

| Replace Worn Out Parts | As Needed | Maintains efficiency and prevents breakdowns | Varies |

| Check Strap Tension Settings | Every Shift | Ensures optimal sealing and reduces waste | 5 minutes |

Troubleshooting Tips for Common Strapping Issues and Failures

Troubleshooting common issues with semi-automatic strapping machines is crucial for maintaining efficiency. According to industry reports, around 30% of operational downtime occurs from equipment failure. This statistic underlines the importance of regular maintenance and vigilance in identifying potential failures.

One common issue is strap misalignment. Misalignment can lead to ineffective strapping, risking package integrity. Check the feed path for debris or damage. Regularly inspect the guide rails. Smaller details might seem insignificant but can cause major interruptions in production. Another frequent failure is strap feeding problems. A worn-out feed roller can struggle to pull the strap properly. Replacing these rollers every six months is recommended to ensure smooth operation.

Operators also face issues like uneven tension. This can lead to poorly secured packages. Over time, tension settings may drift based on usage patterns. Monitoring tension regularly can avert this problem. Ensure operators are consistently trained in best practices. Troubleshooting isn't just about fixing issues. It's also about recognizing the signs early. Awareness and routine checks can enhance machine performance significantly.

Semi Automatic Strapping Machine Performance Analysis

This bar chart represents the common issues faced by semi-automatic strapping machines based on user feedback. The data includes the number of reported issues related to different performance factors.

Related Posts

-

Top 10 Benefits of Using a Plastic Strapping Machine for Packaging Solutions

-

Essential Tips for Choosing the Best Automatic Banding Machine for Your Business

-

Why You Need a Plastic Banding Machine for Your Packaging Operations

-

What is an Automatic Pallet Wrapping Machine and How Does It Work?

-

How to Choose the Best Automatic Pallet Wrapping Machine for Your Business

-

How to Choose the Best Shrink Wrap Machine for Your Business Needs